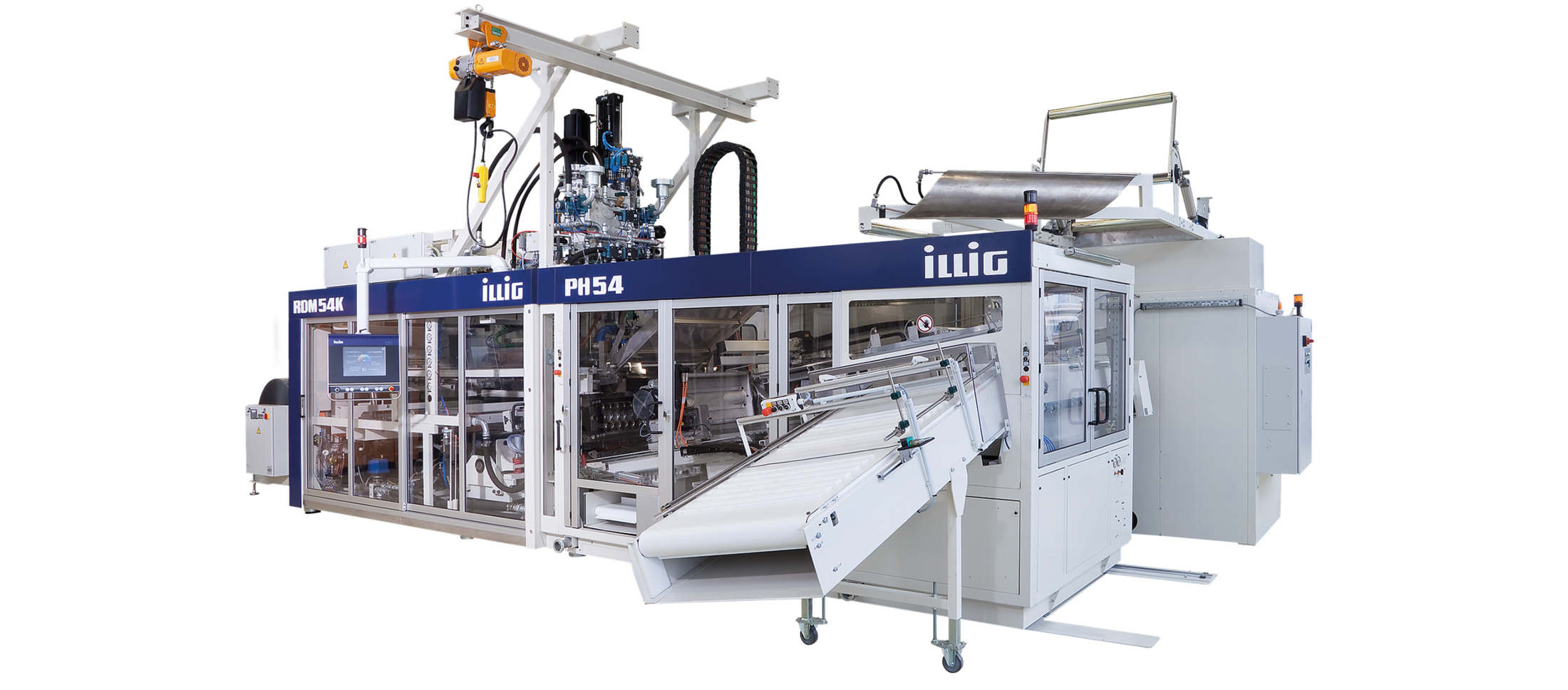

The automatic pressure-forming machine RDM 54K with a forming area of 500 mm x 300 mm processes material film from the roll or inline directly from a connected extruder using combined in-place forming and pass-through punching tools. The ILLIG thermoforming machine is ideal in particular for products with a high draw ratio. The cam-controlled toggle lever system of the forming machine enables high forming and punching forces. The forming table of the K-machines tilts 80° in feed direction after the forming sequence. Ejectors then discharge the cups into the stacking station.

- Cleantivity®

- Automatic default setting calculation

- Guided tool change

- Highest cycle rates Fast build-up Forming pressure

RDM 54K

Automatic roll-fed thermoformer for forming/punching tools

Spare parts

With tool spare parts we offer our customers worldwide optimal support. Safe, reliable, superior parts for guaranteed quality.

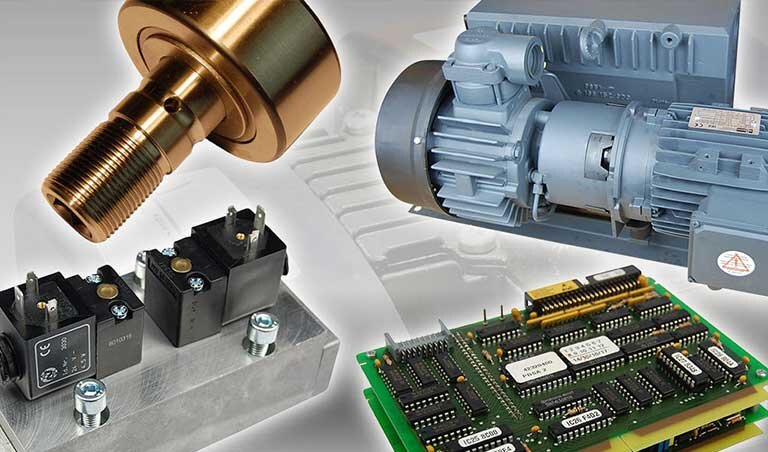

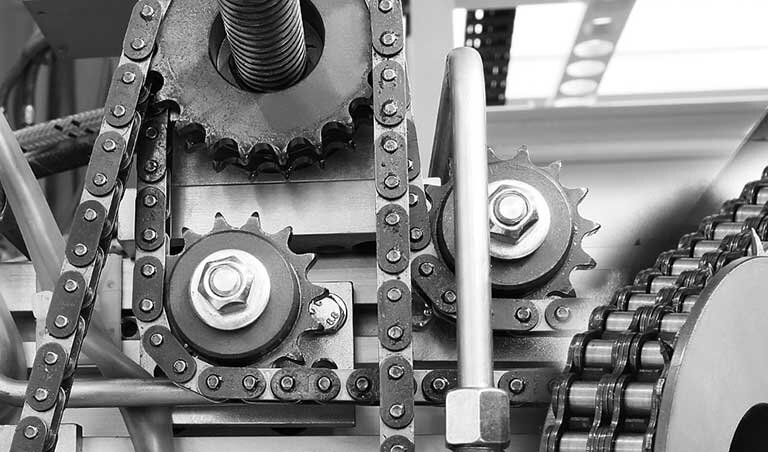

Spare parts

With machine spare parts we offer our customers worldwide optimal support. Safe, reliable, superior parts for guaranteed quality.

Monitoring

Our Monitoring products provide you a competitive advantage. Data analysis via our sercure remote access service, enables you reduced costs and time for trouble shooting and increase the availability of your ILLIG system.

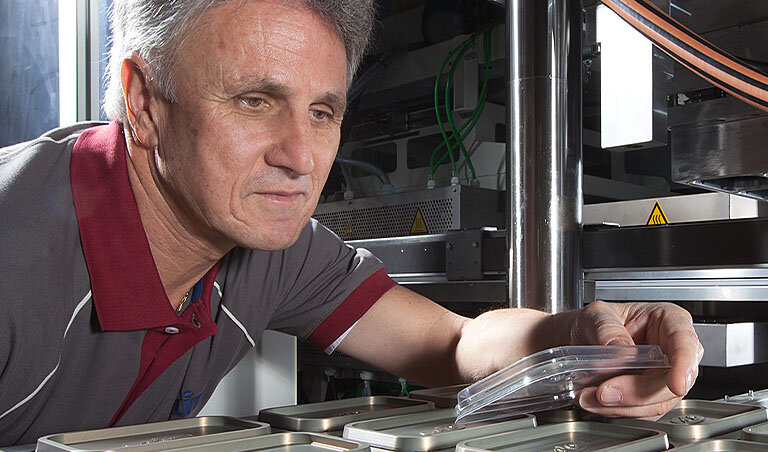

Process improvement

Our experts will help you with production or optimize the entire thermoform process to achieve more performance, better product quality and higher machine availability for your ILLIG system.

Service agreements

With service agreements we provide you support for your ILLIG system over the entire lifecycle.

Technical Services

Technical Services offers our customers worldwide technical support.

Technical Training

Master complexity - increase return. In accordance to this motto we educate the delegates to advanced line specialists.

Upgrades

With upgrades for our machines, our customers can implement new applications and functional enhancements and thus realize new customer requirements, improve profitability and increase their added value in a targeted manner.

Accessories

ILLIG accessories with ILLIG Quality. High-quality materials with a long lifespan, with targeted use, are a guarantee for optimal work results.