ILLIG History

1946

Founding

On May 27, Adolf ILLIG founds a repair shop in the small garage at his parents' house.

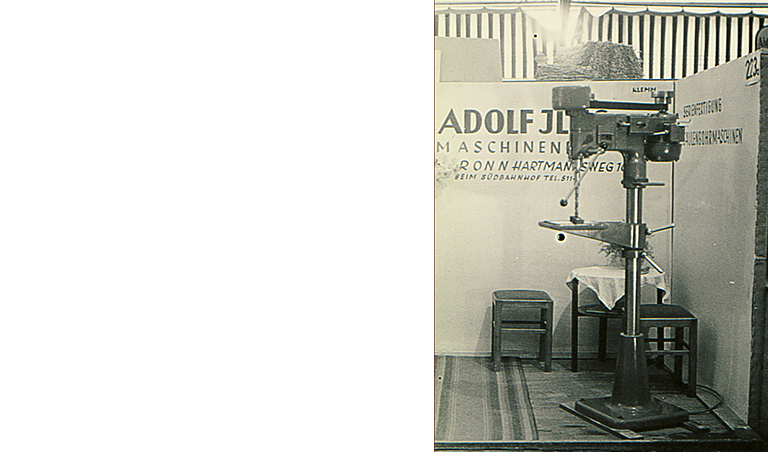

1948

Pillar drilling machine

A pillar drilling machine is the first own product of the company’s founder.

1952

Drier

- Drier production for Passat Maschinenbau.

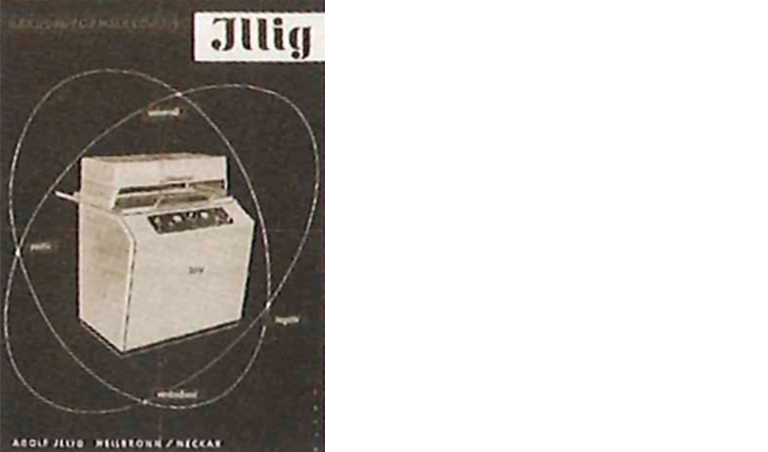

1956

First Thermoformer UA 100

The knowledge gained from both the repair shop and drier production was employed for the first ILLIG thermoforming machine, model UA 100 (UA means universal automatic machine).

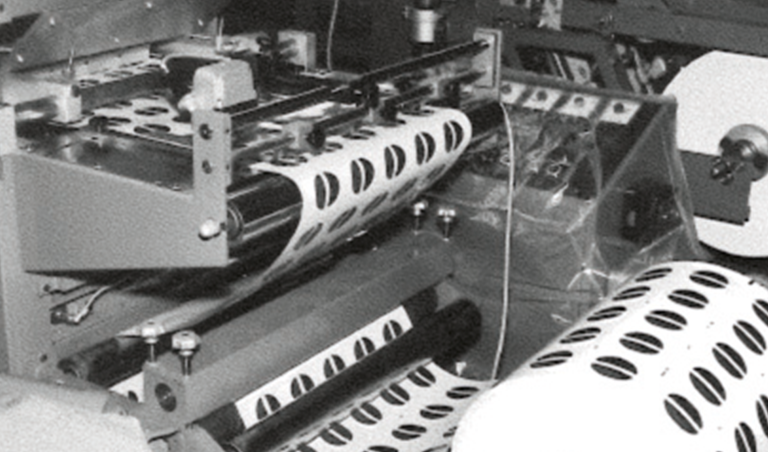

1960

Machine model R 650

Machine model R 650 is presented. It is the first automatic vacuum thermoformer in the world to work from pre-printed roll stock for the production of decorated lids.

1961

New premises

Move to the new premises in Mauerstrasse with now 160 staff members.

1963

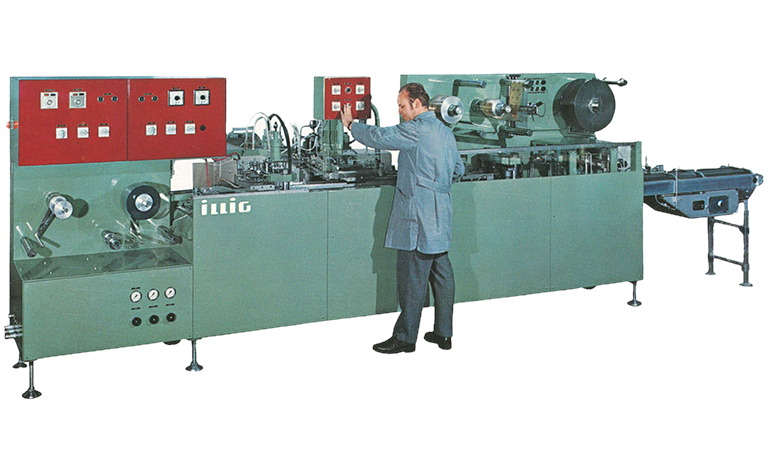

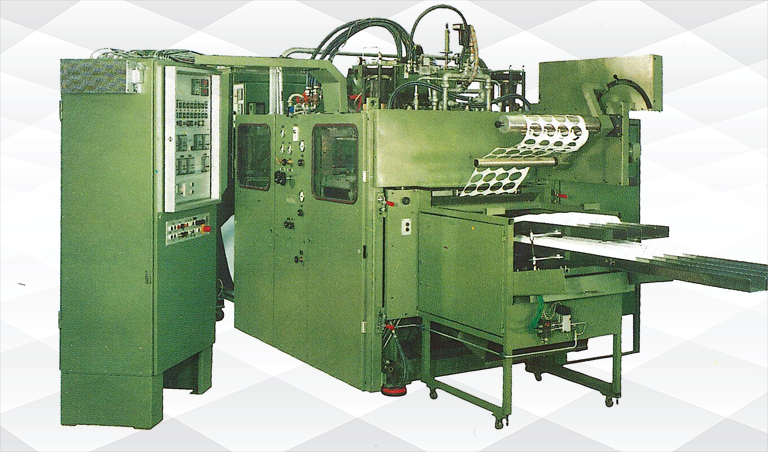

Start of RDM series

Design of the first high-speed automatic pressure forming machine for forming/punching operation. Start of the RDM series with machine model RDM 37/6 which has been very successful ever since.

1964

Founding of mold and tool shop

Further machines types of the RDM series are built. In order to be able to get complete thermoforming lines for cups and lids, a mold and tool shop is founded.

1967

Expansion of production

Drier production is stopped. The space is urgently needed for the expansion of production. Now ILLIG has 480 employees.

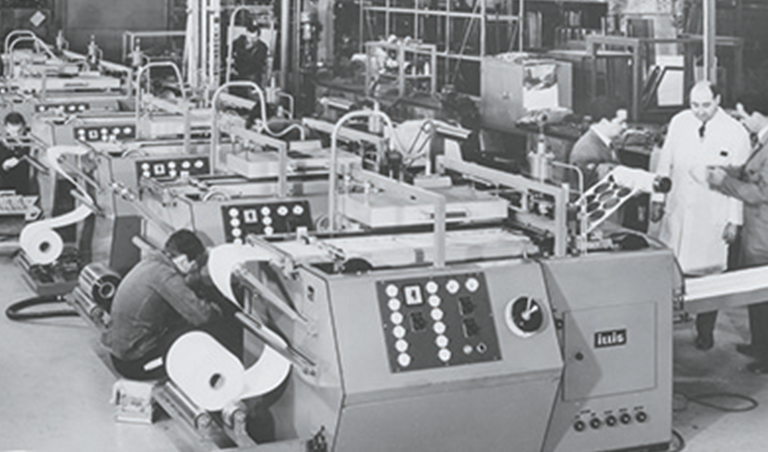

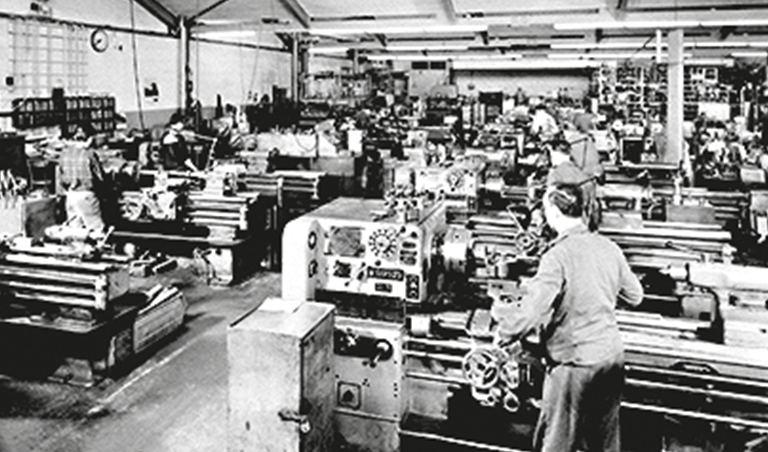

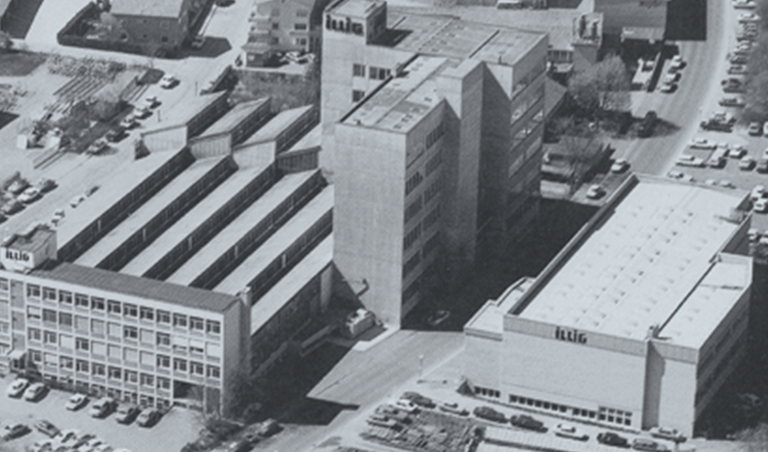

1968

Factory || & first Piston dosing machines

The production department is re-arranged and considerably expanded, after Factory II is finished in 1969. Most machine parts are manufactured in-house. ILLIG has more than 800 employees now.

The first packaging line is built where form, fill and seal functions are integrated. The first piston dosing machines are developed for filling paste-like goods.

1973

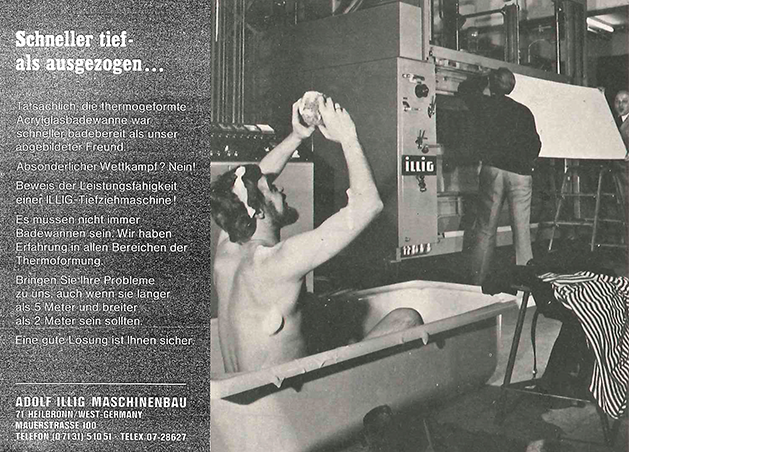

Special machines (PMMA)

ILLIG special machines for the production of bath tubs, sinks and other products out of PMMA (acrylic glass) promote a revolution in the sanitary sector in this year. Steel and porcelain articles are replaced more and more by acrylic glass.

1976

ILLIG FRANCE

ILLIG FRANCE - first branch office which is founded abroad.

1978

North | Assembly hall

Since thermoforming lines are getting bigger, the assembly department needs to be restructured. North I assembly hall is built.

1983

ILLIG UK & developing of pre-heater

ILLIG UK takes over service and sales for Great Britain. ILLIG develops the pre-heater (VHW) equipped with heated aluminum rollers for continuous PP heating.

1984

Tilt technology

For the first time ILLIG uses tilt technology in larger thermoforming machines with machine model RDM 50K. Thus a new standard is created in the packaging production with respect to hygiene conditions.

1989

Developing of calculation program

Development of the first calculation program for automatic calculation of the basic setting of automatic vacuum thermoforming machines.

1991

Customer training

Customer training is relocated to new rooms and intensified.

The production department is expanded with a new building and innovative production techniques can be introduced.

1993

New Center& IML-T®

The new Center for apprentices opens. Up to 50 young people undergo vocational training in the metal sector.

Development of the first in-mold labeling production line for applying PP labels to PP margarine tubs.

1994

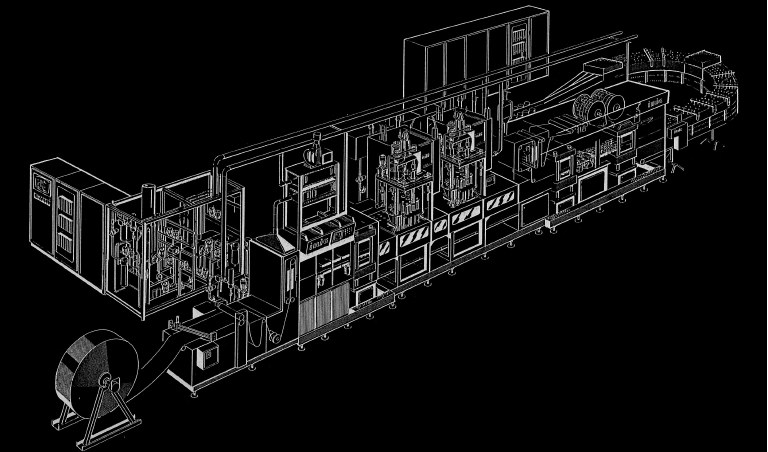

Form, fill and seal lines

Fully aseptic form, fill and seal lines are built with a daily capacity of 700.000 yogurt cups.

1995

Improved mold designs

Improved mold designs for forming/punching technology are developed which set the standard with respect to precision, temperature control technology and service lives.

1996

ILLIG FAR EAST & ILLIG USA

ILLIG FAR EAST and ILLIG USA open as Service and Spare Parts Centers.

1997

ILLIG LATIN AMERICA & New premises

ILLIG LATIN AMERICA becomes a Service and Spare Parts Center. Productive start of SAP/R3 in all sectors of the company in 2000 and introduction of the material and traffic flow concept including Mauerstrasse which now belongs to the premises.

2001

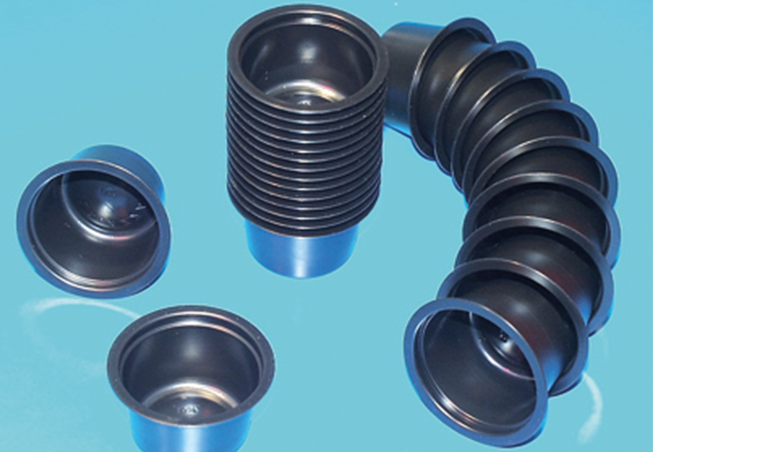

Plastic capsule

Birth of plastic capsule. Development of the first coffee capsule mold. A plastic material with barrier properties is employed.

2002

Expand in ILLIG USA

ILLIG L.P. USA Service and Spare Parts Organization is expanded by a sales organization.

2003

Maybach Price

ILILLIG apprentices repeatedly receive Maybach Price for excellent performance.

2004

RDM 78K 3rd Generation

ILLIG JAPAN takes over Sales and Service Organization. With RDM 78K, the first 3rd Generation thermoformer starts production at customer.

2005

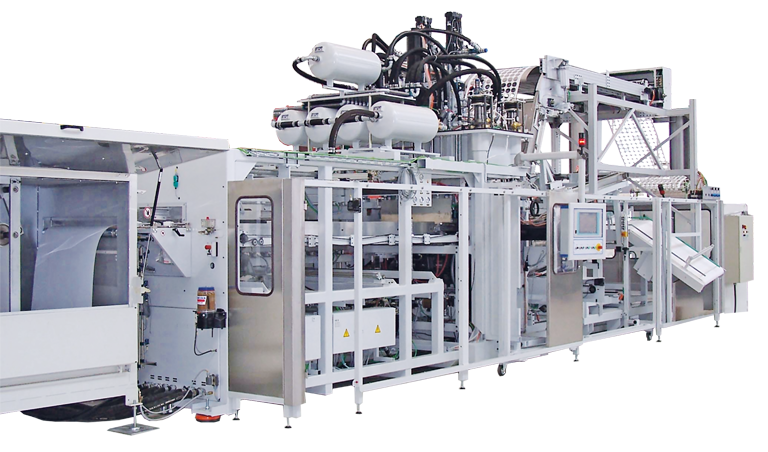

IML-T® for form, fill and seal lines

In-mold labeling for form, fill and seal lines is presented for the first time.

2006

Step by step convertion to 3rd Generation

Step by step all high-performance thermoformers are converted to 3rd Generation.

2008

World premiere BF 70

BF 70, the first undercut thermoformer of this kind worldwide is presented ready for production.

2013

ILLIG IC-Machines

Intelligent control concept for automatic thermoformers for the first time.

By developing the IC machines (Intelligent Control Concept) ILLIG engineers succeeded in making a quantum leap in thermoforming.

2015

IML-T® Decoration Technology

IML-T® decoration technology establishes itself. In-mold labeling lines conquer the market.

2016

Cleantivity®

With Cleantivity® ILLIG sets a milestone for clean production processes in thermoforming moulding with high quality time.

2017

Pactivity®

The customised packaging development "Pactivity® 360" supports and accompanies customers from the initial packaging idea to the production system.

2018

New Packaging System

Development of the new packaging system HSU 35b. Especially the all paper blisters conquer the packaging industry.

ILLIG CHINA

ILLIG CHINA is established near Shanghai and opens as a Customer Solution Center with its own showroom.

2019

Circular Thinking

ILLIG offers numerous sustainable solutions and new developments under the umbrella of "Circular Thinking".

The first fourth-generation IC-RDM 76K thermoformer is launched.

New Production Site

ILLIG ROMANIA in Sibiu is opened as a further production site.

2020

I-PACK®

With its I-PACK® brand (ILLIG intelligent packaging) ILLIG presents sustainable plastic-cardboard combinations that are are easy to separate.

2021

World Premiere in China

World premiere of the RDF 85 at the Chinaplas plastics trade fair. ILLIG introduces the segments RedLine and BlueLine.

75 Years ILLIG

The company ILLIG celebrates its 75th anniversary. With the motto "Next 75", the company is consciously looking ahead to extend its market leadership in the decades to come.