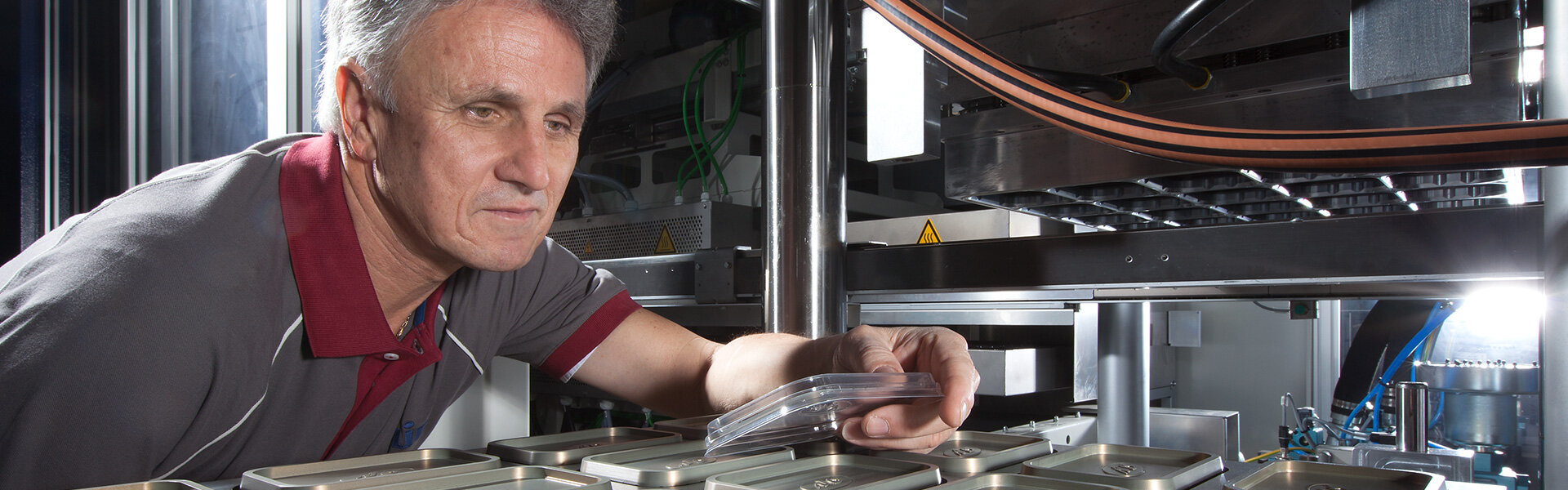

Service | Technical Services

Technical Services offers our customers worldwide technical support. From commissioning and repair through to process improvement. With Technical Services, we support our customers in the complete life cycle of ILLIG thermoforming systems.

We're here for you, whether by phone, data channel or in person. Our team is made up of professionals with years of experience.

The service hotline is available for you from Monday to Saturday, offering you immediate professional assistance with all your concerns.

Benefits

- Quick and competent assistance for urgent problems

- Immediate identification of a malfunction via remote access to your machine

- Initiation of problem-specific assistance

- Management of service deployments

- Increased machine availability

- Restoration of normal operating conditions/avoidance of extended downtimes

Hotline service tools

Solving problems and failures of ILLIG tools in production to restore the expected machine productivity as quickly as possible.

Health Check

A Health Check is a diagnosis of the state of your ILLIG machine that indicates which wear parts must be replaced to ensure that your ILLIG machine continues to operate properly.

Benefits

- Minimize unscheduled downtimes

- Constant productivity and machine availability

- Recommendation of actions to eliminate the causes such as inspection, settings, replacement of wear parts

- ILLIG Service recommends appropriate spare part sets that are based on the experience of our specialists

Repairs

Replacement of critical or worn parts and rectification of performance values that lie outside of specified tolerances, so as to restore the expected machine productivity and avoid substantial downtimes.

Benefits

- Very quick and responsive technical support through a global network of service technicians

- Efficient support of the maintenance process

- Minimizing of unscheduled downtimes

- Use of original high-quality ILLIG replacement parts

Maintenance

Preventive maintenance of ILLIG machines in conjunction with the deployment of a service technician to substantially reduce the risk of downtime.

Machine relocation

Carefully planned relocation of ILLIG machines based on customer-specific requirements.

Initial operation

Assembly and initial operation of an ILLIG machine.

Tool maintenance

Inspection, overhaul and repair of worn out or damaged ILLIG tools

Advantages of tool maintenance

- Less downtimes

- Increased productivity

- Inspection and complete overhaul of your tool

- Original ILLIG spare parts

- Wear part analysis

- Replacement of worn-out or damaged parts

- A comprehensive service report

In-house tool maintenance

On-site tool maintenance and repair at the customer's facilities of exisitng tools and also the installation of new tools in the machine.

Procedure for on-site maintenance

- Dismantling of your tool at your production plant by a professional ILLIG service technician

- Maintenance work and support, as well as a tool and wear part analysis

- Installation of ILLIG spare parts on site

Request your individual offer now

We are happy to advise you on the details of the individual packages