Pactivity® 360 | 360° Packaging Development

From the Packaging Idea to your Tool- and Production System

ILLIG has decades of experience developing packaging and helping packaging manufacturers. Each project is treated independently, as no packaging is ever exactly the same. Development begins with the customer's initial idea and ends with an outstanding final product that meets all requirements. This entails numerous steps in between and several answers that have to be found to technical challenges along the way. Packaging for fresh fruits and produce is a good example of how multifaceted packaging can be. It has to ensure visibility of it contents, while also protecting them, and it must be suitable for transport, both to the market and throughout the logistics process. ILLIG packaging experts develop different variants for ventilation (hole vents or closure knobs with spacing for clamshell trays) and package closure (hinged lids, separate lids or without). Product, packaging material, volume and feasibility as well as decoration with IML-T® – all have to be analyzed to determine the design possibilities, a tool layout and line concept, because thermoforming offers a wide variety of different methods to produce packaging. The thermoforming method depends primarily on the required properties of the packaging. The decisive factors include design, desired material, and required output. Once the initial criteria have been successfully determined in the packaging development stage, an extensive testing phase follows that begins with the production of samples. This is followed by a number of required product tests and finally ends with the customer approval. Only then can work begin on the production system. ILLIG has the necessary know-how in tool making and machine construction and is familiar with all the technical requirements – world-wide.

- Application

(formed part / requirements) - Idea

(briefing of the possibilities) - Analysis

(all relevant options are explored) - Know-how

(the packaging is developed while taking into account all the processes in the supply chain) - Test phase

(sample creation / sample tool) - Production system

(final configuration of line)

360° Custom-made Packaging Development in Thermoforming

Application (formed part / requirements)

Support from experienced packaging consultants. Together, the properties (application profile) are defined, which serve as the foundation for creating a quotation for the packaging development.

Packaging development

Idea (briefing of the possibilities)

Analysis (all relevant options are explored)

Know-how (the packaging is developed while taking into account all the processes in the supply chain)

In principle, each project is treated independently, whether confidential or not, as no packaging is ever exactly the same. Development begins with your initial ideas and ends with the final product that meets all requirements. This entails numerous steps in between and answers that have to be found to technical challenges along the way. Packaging has to ensure visibility of its contents while also protecting it from outside elements, and it has to be suitable for transport and logistics processes. The entire process of the supply chain is analyzed. ILLIG regards the development of thermoformed packaging under sustainable aspects from the beginning to the point of reuse and considers the possibilities of optimal packaging recycling when selecting packaging-materials. ILLIG packaging experts develop different variants for ventilation (hole vents or closure knobs with spacing for clamshell trays) and even closure (hinged lids, separate lids). Product, packaging material, volume and feasibility all have to be analyzed to determine the design possibilities, a tool layout and line concept.

Test phase (sample creation / sample tool)

The thermoforming method depends primarily on the required properties of the packaging. The decisive factors include design, desired material, and required output. Once the initial criteria have been determined in the packaging development phase, a phase of extensive testing follows that begins with the creation of a sample, followed by a number of required product tests and finally ends with your approval.

Production system (final configuration of line)

ILLIG has the necessary know-how in tool making and machine construction and is familiar with all the technical requirements. The machine line is configured together with experienced engineers according to the pre-defined packaging solution. Work can then begin on the production system.

ILLIG Pactivity®

We provide customer support with respect to optimum packaging solutions. In 2017 we presented this trendsetting concept under the slogan „Pactivity® 360° - Customized packaging development“ on occasion of Interpack, the global leading trade fair of the packaging industry. For quite a long time we

have been involved in packaging development. We defined this sector in many respects and details and created this brand. As it becomes apparent today,

Pactivity® topics, such as resource-saving and recyclable packages, single material packages, processing of recyclates, upcycling as well as thermoforming

of bio-based and biologically degradable plastics are top issues. These topics will be hot issues at the largest plastic trade fair, K-show, Dusseldorf (Germany),

October 2019. We are very well prepared for this, also with respect to our technology.

Examples for packaging development

Coffee capsules

Packaging development coffee capsules

- Application | Coffee capsules

- Idea | Development of portion packs out of plastic material with

barrier properties (some with hole punched in capsule) - Analysis | Product, material, volume, feasibility, etc.

- Know-how | Design options, mold design, line concept

- Test phase | Production of samples, tests, verifications, approval

- Production system | Configuration, realization, design, production,

approval by customer

Fruit and vegetables

Packaging development fruit and vegetables

- Application | Packs for fruit and vegetables

- Idea | Development of variants for ventilation and closure

- Analysis | Product, material, volume, feasibility, etc.

- Know-how | Design options, mold design, line concept

- Test phase | Production of samples, tests, verifications, approval

- Production system | Configuration, realization, design, production,

approval by customer

Curd with and without ingredients

Packaging development Curd with and without ingredients

- Application | FFS pack 'Curd with and without ingredients'

- Idea | New pack design

- Analysis | Product, material, volume, feasibility, etc.

- Know-how | Design options, mold design, line concept

- Test phase | Production of samples, tests, verifications, approval

- Production system | Configuration, realization, design, production,

approval by customer

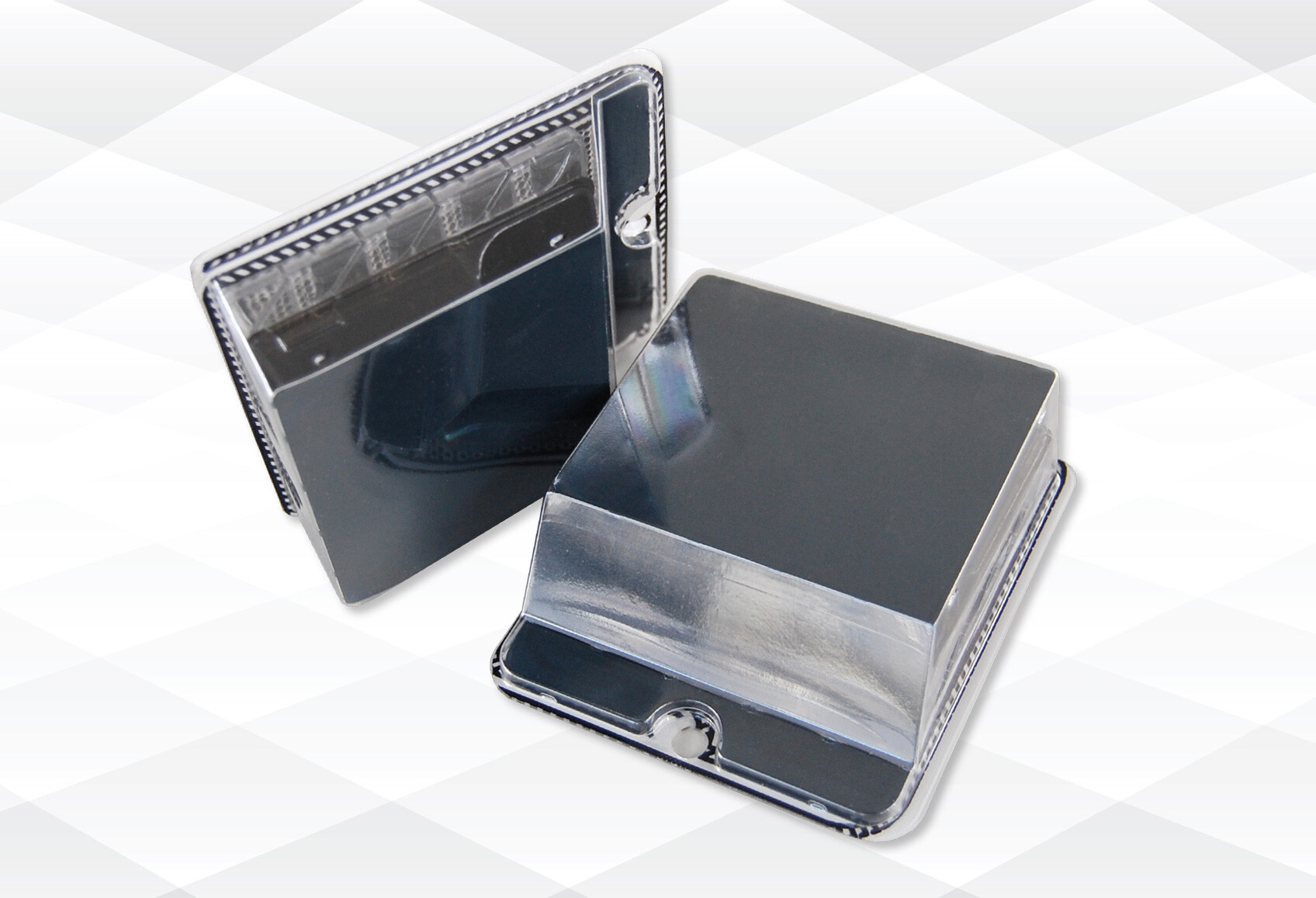

Razor pack

Packaging development razor pack

- Application | Razor pack

- Idea | New pack design

- Analysis | Product, material, volume, feasibility, etc.

- Know-how | Design options, mold design, line concept

- Test phase | Production of samples, tests, verifications, approval

- Production system | Configuration, realization, design, production,

approval by customer