Circular Thinking

Plastics essential elements of our everyday lives

Plastics are the resources of the 21st century and can be processed effectively across industries in very different and flexible manners and at the same time they can be re-used in a resource-saving way. Plastics provide benefits for health, sustainability and convenience. They contribute to ensuring and improving the standard of living, hygiene and nutrition. For quite some time now plastics and plastic packages have been in the public focus. Insufficient or missing waste collection systems in major regions of the world have caused marine and environmental littering. From our point of view it is wrong to meet these challenges in a biased way by prohibition and highly emotional campaigns. The development and expansion of circular recycling systems and a resource-saving use of plastic materials are suitable approaches. This includes the development and implementation of technical solutions. We are a system supplier of machines and tools for thermoforming and have been realizing these solutions for years. In terms of ecological considerations it is not always the best choice to turn away from plastics and towards supposedly better alternatives - frequently, this is only used as alibi. By creating this page we want to contribute to a de-emotionalization of the issue. And we also want to offer new approaches for responsible plastic handling.

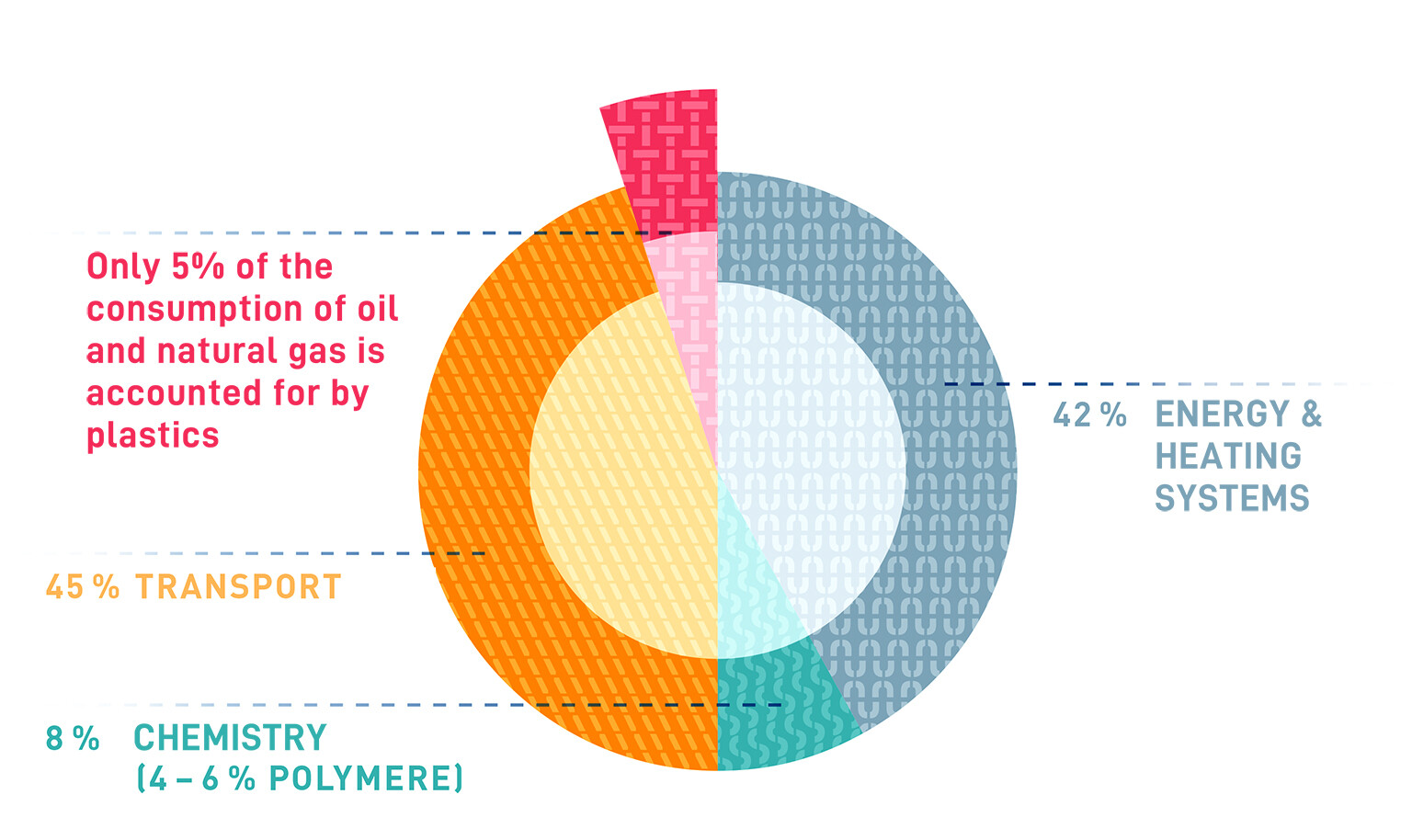

Share of plastics of the total mineral oil and natural gas consumption in Western Europe and Germany

Only approx. 1.8 % of the mineral oil and natural gas consumption can be

attributed to packages.

Source: Conversio 2018

Responsible use of plastics

In 2018 plastics and the plastics industry shifted more and more into the focus of public awareness. Particularly plastic packages ever since then have been standing for environmental pollution and a waste of resources. But plastics are versatile and they are useful solution providers which help to tackle a number of the challenges facing our society today. However, not everything in everyday life is going well when it comes to plastic handling. A lot of products end up somewhere in the environment after use, disposed of much too thoughtlessly. This applies to packages and single-use plastic products which currently are particularly in the focus of European politics. And we often forget that these plastic applications provide important benefits.

Less food loss, portionability, multiple use, low material consumption, positive environmental balance (positive ecological footprint, since positive CO2 balance) and many more aspects. Plastic material has turned into a keyword for something which is inferior, artificial and harmful. But a clear view is absolutely essential. Plastics themselves are not the problem. On the contrary, the material is frequently part of solutions which are often vital.

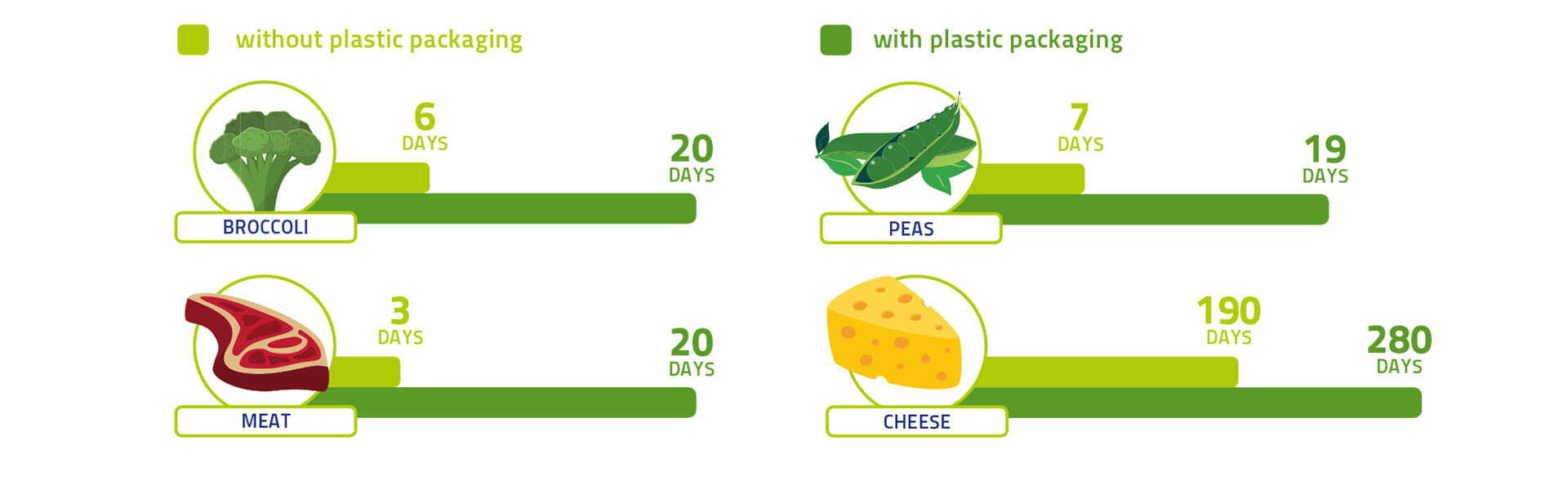

Longer lasting thanks to plastic

Source: Flexible Packaging Association (FPA)

"If consumers want a wide selection of

fresh food, packages are essential."

Ulf Kelterborn, CEO Industrievereinigung Kunststoffverpackungen e.V.

Collecting, recycling, circular economy

Solutions against environmental littering are simple on one hand and complex on the other hand: Plastic materials are far too precious to be thrown away. The European Commission also realized this and as a result a plastic strategy was submitted in the beginning of 2018 with the intent to create first approaches for improved plastic processing in the circular economy. Initially, the European Parliament and the Council decided on prohibitions with respect to placement of so-called “Single use plastic articles” on the market: According to these initiatives it is no longer allowed to offer cutlery and stirrers, drinking straws, party cups or cotton swabs out of plastic material in the near future. But it is still unclear how a Europe-wide uniform implementation can be accomplished. The Federal Ministry of Education and Research has offered 35 million Euro for research on "Plastics in the Environment" through the "Research for Sustainable Development" program with the intent to develop and establish scientific procedures, methods, instruments and terms in the overall context of the "Plastics in the Environment" issue.

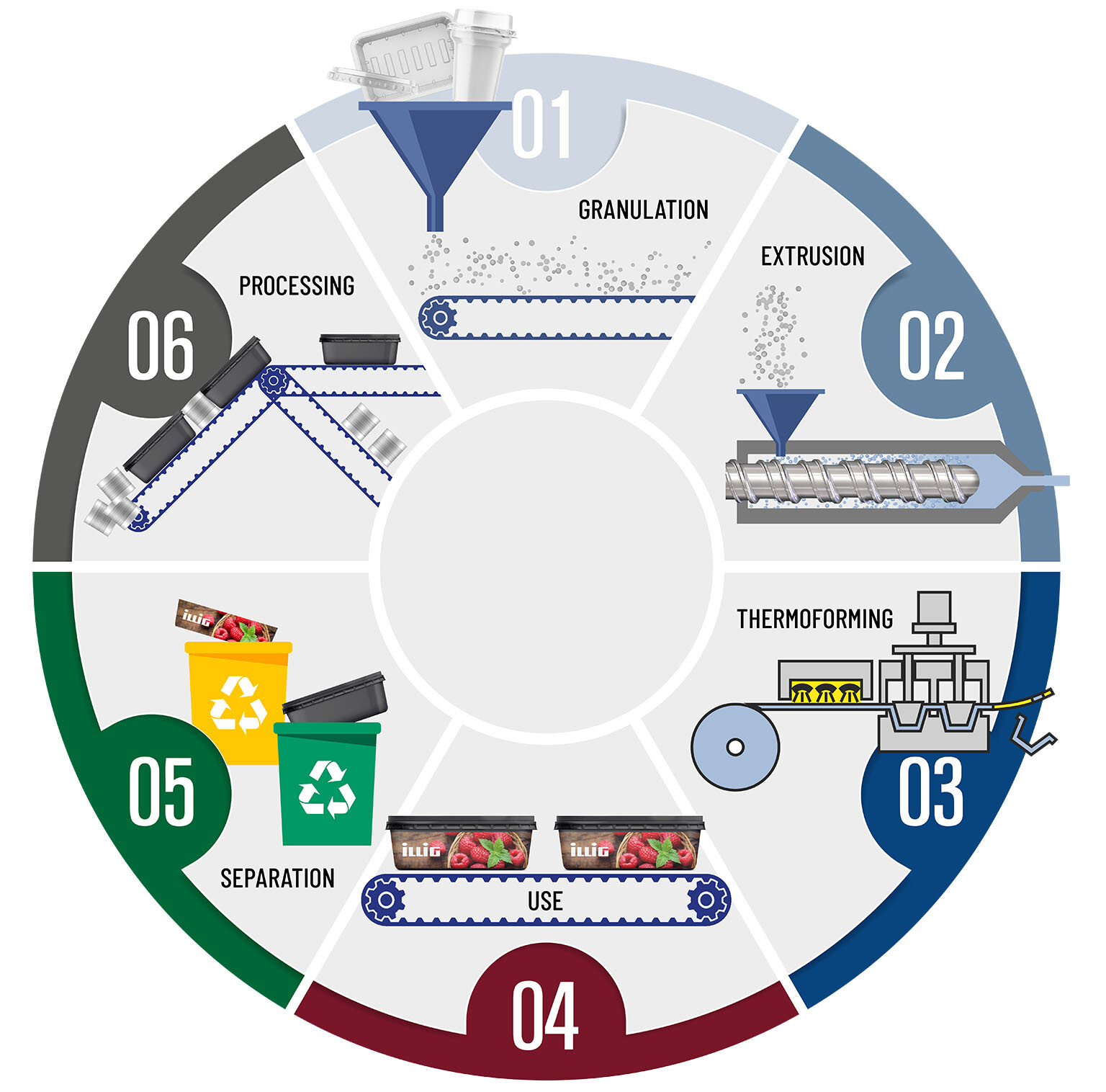

Circular Thinking bei ILLIG

- Recycling companies recycle the plastic raw material

- Different materials, such as sheet or roll material, can be manufactured out of plastic granulate

- ILLIG customers manufacture products out of the materials

- Consumers and companies utilize and subsequently dispose of the products

- Consumers separate the packages in a single-variety manner

- Waste disposal companies supply the plastic material to recycling companies

"I do not believe that plastics canbe quickly replaced. Plastic packages provide many benefits: They are very thin, lightweight and equipped with barrier properties."

Sven Sängerlaub,Fraunhofer Institute for Process Engineering and Packaging IVV (Source: dpa)

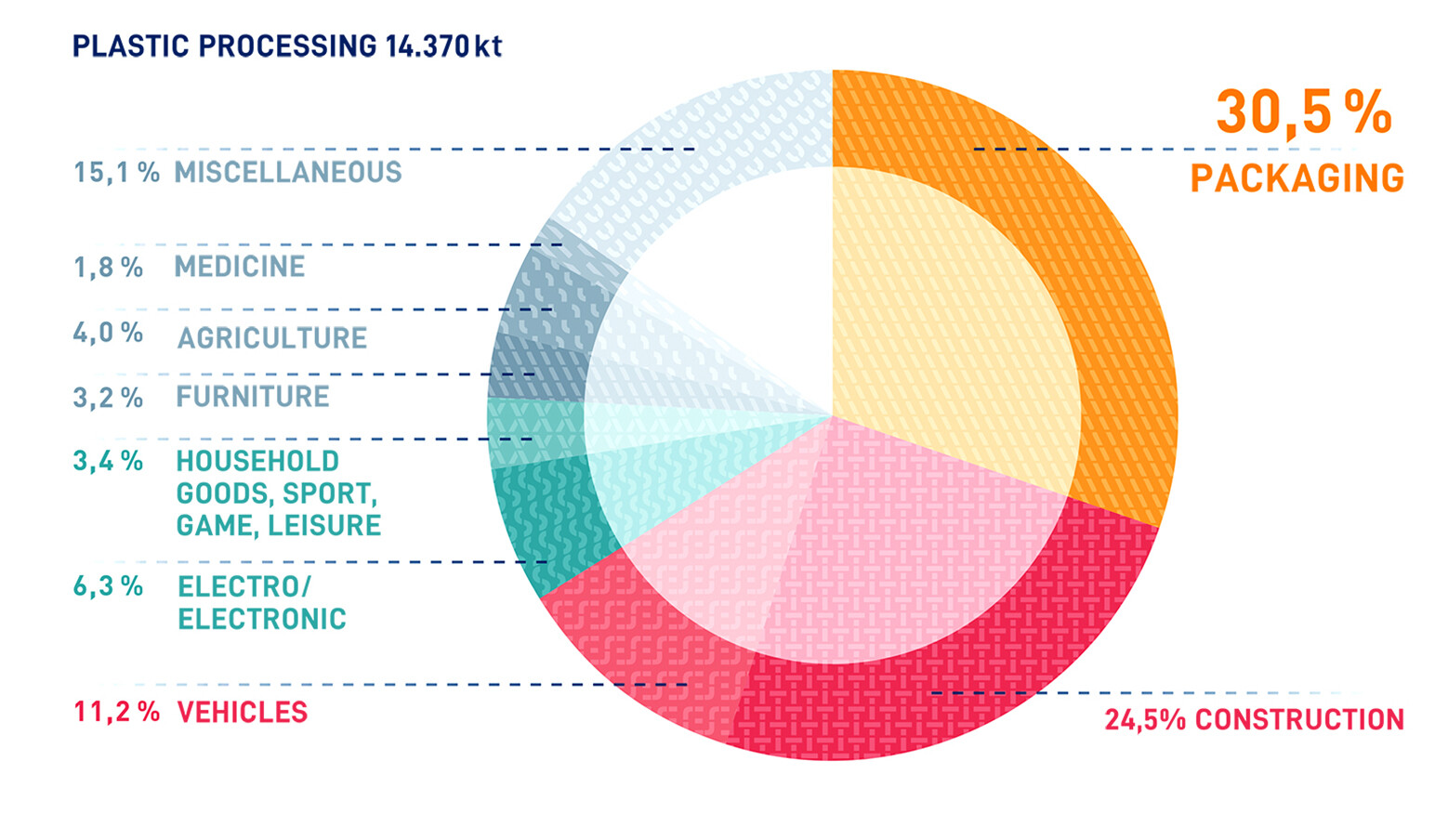

Quelle: PlasticsEurope

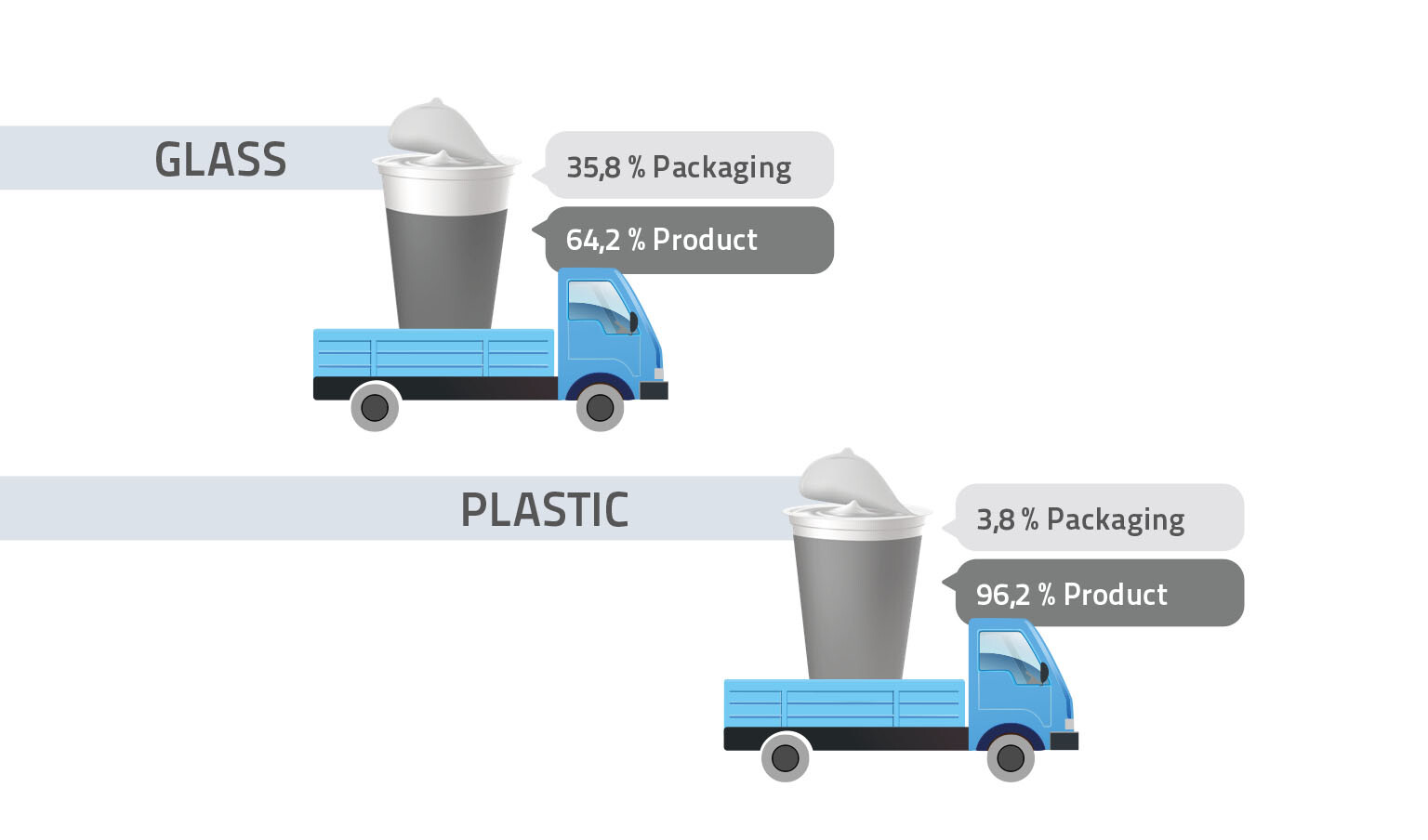

50 % of all packaged goods are packed in plastic materials

However, all plastic packages together only represent 17 % of the total weight of all packages

ILLIG offers technically sustainable solutions

It is not just since the public discussions whether plastic packages are useful or whether they just cause marine litter, that ILLIG developed technical solutions which allow plastic materials to be processed in a most sustainable way on its machines and tool systems. We utilize our know-how and information to achieve sustainable process and value creation chains for packaging design, material selection, tool and machine design.

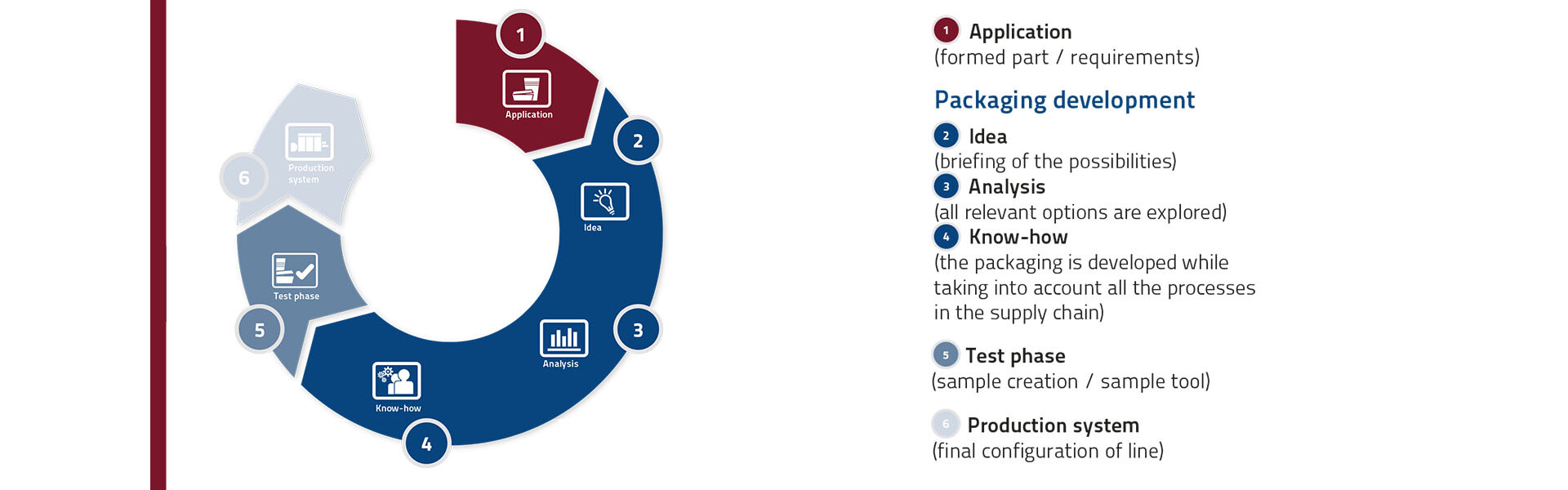

For many years we have been involved in packaging development and in this way we support package manufacturers in “Design4recycling”. From the initial product idea to the realization of corresponding tool and production systems, numerous requirements must be met. Together with our customers we develop solutions in the course of these processes and offer our development support for thermoformed packages. Everything from one source: ILLIG regards the development of a thermoformed package from the viewpoint of sustainability – from production to re-use – while already concentrating on optimum package recycling at the material selection stage.

"In our opinion, biased problematization of materials and prohibition are not really helpful. Moreover, a change in attitude is required; a shift from the throwaway mentality to the development of a circular economy. The relevant proposals of the EU Commission are steps in the right direction and should be the goal of joint efforts on a national, European and global level. The plastics industry contributes its share and already today they are active in numerous initiatives and projects worldwide."

Dr. Rüdiger Baunemann (†), 2019 CEO PlasticsEurope Deutschland e. V.ILLIG Pactivity®

We provide customer support with respect to optimum packaging solutions. In 2017 we presented this trendsetting concept under the slogan „Pactivity® 360° - Customized packaging development“ on occasion of Interpack, the global leading trade fair of the packaging industry. For quite a long time we have been involved in packaging development. We defined this sector in many respects and details and created this brand. As it becomes apparent today, Pactivity® topics, such as resource-saving and recyclable packages, single material packages, processing of recyclates, upcycling as well as thermoforming of bio-based and biologically degradable plastics are top issues. These topics will be hot issues at the largest plastic trade fair, K-show, Düsseldorf (Germany), October 2019.

360° custom-made packaging development in thermoforming

From the first idea to packaging and production system

Still creating high standards

Life as we know it here in the industrial countries, where we benefit from high standards in food safety and supply, medicine and hygiene, infrastructure and logistics, traffic and energy, will almost be impossible without the versatile use of plastics and plastic packages. If we look beyond the horizon, it becomes obvious that particularly in the developing countries and the emerging markets the packlog demand for plastic packages is high due to the high hygiene standard.

Quelle: PlasticsEurope

ILLIG develops new, sustainable IML-T® application

Numerous new packaging variants were developed – particularly in connection with the ILLIG IML-T® technology – such as IML-T® Cardboard (plastic-cardboard combination package) which was presented to the public. The application was developed specifically for the new “Circular Thinking” market demands and can be manufactured on ILLIG systems. In the development stage we paid special attention to preserving the well-known quality. Moreover, the existing technology was improved and new aspects were included. Easy separation of plastic and cardboard materials is the benefit provided by this package and consequently optimum recycling is possible. A further benefit provided by the ILLIG world is the production of all-cardboard blisters on ILLIG packaging systems.

Pactivity® also involves the configuration or new development of the optimum packaging system by ILLIG for the production of the corresponding package: Tool systems used in lines are getting more and more important in this development process. ILLIG production systems feature high availability and they are equipped with many options for process monitoring and control. The output of the entire system can be additionally increased thanks to numerous parameters of the tool systems. ILLIG derived the consistent TOOLSYS® tool concept from this.

"For decades, we have been manufacturing

flexible machine and tool systems which allow the production of efficient, recyclable packaging applications."

Karl Schäuble, Managing Director ILLIG

ILLIG, the technology leader, is continuously

developing new solutions

Optimized packages allow raw material reduction and they can be suitable for later recycling. Thermoformed packages, in particular, can be manufactured in a thin-walled, resource-saving and economic way. Besides conventional plastic materials, the use of alternative and new materials is possible in thermoforming. Current ILLIG thermoforming and tool systems are suitable for processing bio-based and biologically degradable plastics, recyclates as well as material combinations. High-quality, safe and recyclable products can be manufactured out of these materials for the global market.

Up-Cycling development project

ILLIG successfully concluded an up-cycling project together with two companies. We managed to extrude a heat-stable PET-C material out of low-value, multi-colored flakes of PET-A bottles and form this material into high-quality menu trays on ILLIG thermoformers. This process can be realized technically without problem and closes a gap in the PET circular recycling system.

IILLIG produced a sustainable fruit tray on a UA sheet processing machine out of ecovio®, a bio-degradable plastic material by BASF SE.

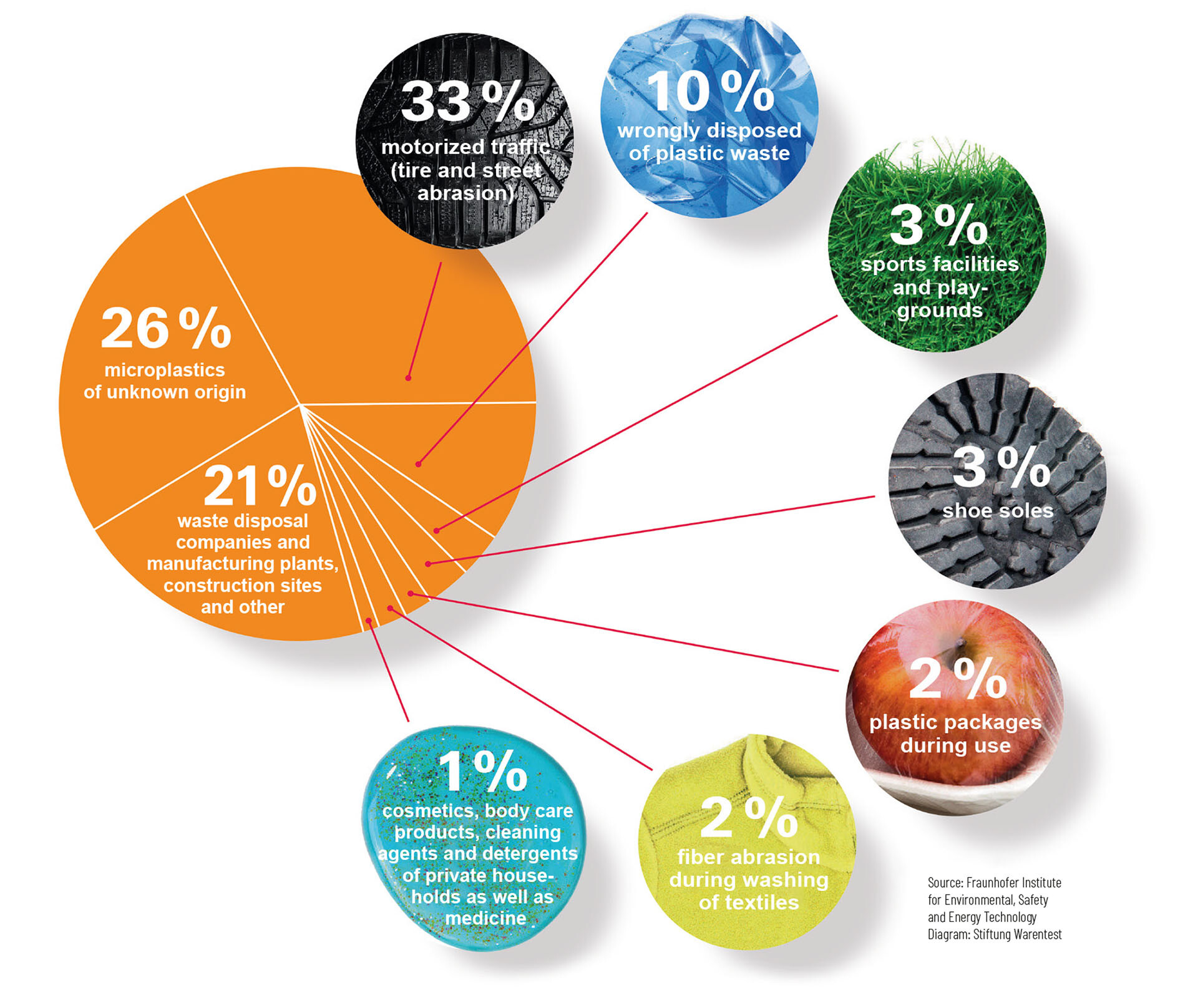

Information on microplastics

Stiftung Warentest calls plastic particles at a size of 0.1 microns to 5 millimeters microplastics and they thus follow the definition of the European Food Safety Authority (Efsa).

Microplastics escape into the environment from at least 51 different sources. The largest source of small particles is motorized traffic. But pedestrians alsogenerate microplastics – abrasion from their shoe soles.