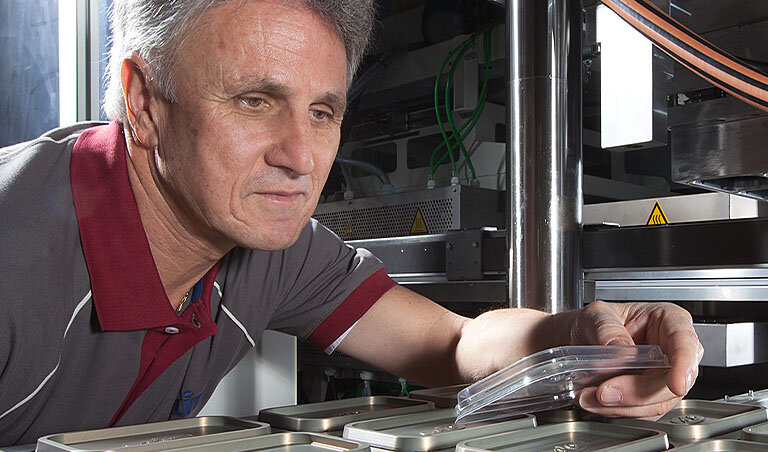

With its PH series product handling systems, ILLIG offers a variety of different stacking systems depending on the technical properties of the thermoforming machine in the production line. Because the product properties also depend on the quality and reliability of the downstream machines in the production line. The different stacking stations range from a simple manual part removal to a fully automated stacking system with feed units to downstream machines, such as a cup rim rolling machine, bag or sleeve packer, and more. The formed parts are either moved directly into a stacking magazine with an ejector in the tool, or picked up and held in place by a vacuum system during the transfer phase and then stacked. This avoids deforming the formed part and improves part cooling.

- Cleantivity®

- Automatic default setting calculation

- Guided tool change

PH 54c

Stacking devicePH 70c

Stacking devicePH 73

Stacking devicePH 75c

Stacking devicePH 76

Stacking devicePH 78

Stacking device

Spare parts

With machine spare parts we offer our customers worldwide optimal support. Safe, reliable, superior parts for guaranteed quality.

Spare parts

With tool spare parts we offer our customers worldwide optimal support. Safe, reliable, superior parts for guaranteed quality.

Monitoring

Our Monitoring products provide you a competitive advantage. Data analysis via our sercure remote access service, enables you reduced costs and time for trouble shooting and increase the availability of your ILLIG system.

Process improvement

Our experts will help you with production or optimize the entire thermoform process to achieve more performance, better product quality and higher machine availability for your ILLIG system.

Service agreements

With service agreements we provide you support for your ILLIG system over the entire lifecycle.

Technical Services

Technical Services offers our customers worldwide technical support.

Technical Training

Master complexity - increase return. In accordance to this motto we educate the delegates to advanced line specialists.

Accessories

ILLIG accessories with ILLIG Quality. High-quality materials with a long lifespan, with targeted use, are a guarantee for optimal work results.