K 2019

ILLIG at the K 2019

The safe choice: Productivity, Decoration, Design4Recycling

- K motto: „Circular Thinking by ILLIG – The safe choice!”

- Therformance: First 4th Generation Thermoformer

- World premiere: First brilliant lid decoration with IML-T®

- Packaging lab with many Design4Recycling solutions

- ILLIG Toolsys – Perfect tool systems

- Digital transformation to Industry 4.0 in thermoforming

Heilbronn/Düsseldorf, October 16, 2019 – ILLIG Maschinenbau will be showcasing several technological world premieres and numerous sustainable packaging solutions at the industry's most important trade fair, the K 2019 in Düsseldorf, from October 16 to 23. „Circular Thinking by ILLIG – The safe choice!“ is the motto of the trade fair presentation in hall 3, stand A 52. For the first time ILLIG will present the RDM 76K 4G thermoforming system which was developed into the 4th Generation with a completely new drive system and a considerably higher level of performance. At the trade fair the line produces drinking cups out of rPET. A further innovation is IC-RDKL, the IML-T® unit, suitable for brilliant decoration of thermoformed lids. The corresponding IC-RDK 80 production line with integrated IC-RDKL unit and interlinked product handling produces round rPET lids with applied paper labels. Presentations on Design4Recycling solutions and cooperation projects will be given at the packaging lab integrated in the trade fair stand. ILLIG will take the trade fair as an occasion to present Toolsys, joined-up expertise regarding tool systems. Moreover, the company points the way to digital transformation in thermoforming by offering several products.

4th Generation Therformance – Performance in Thermoforming

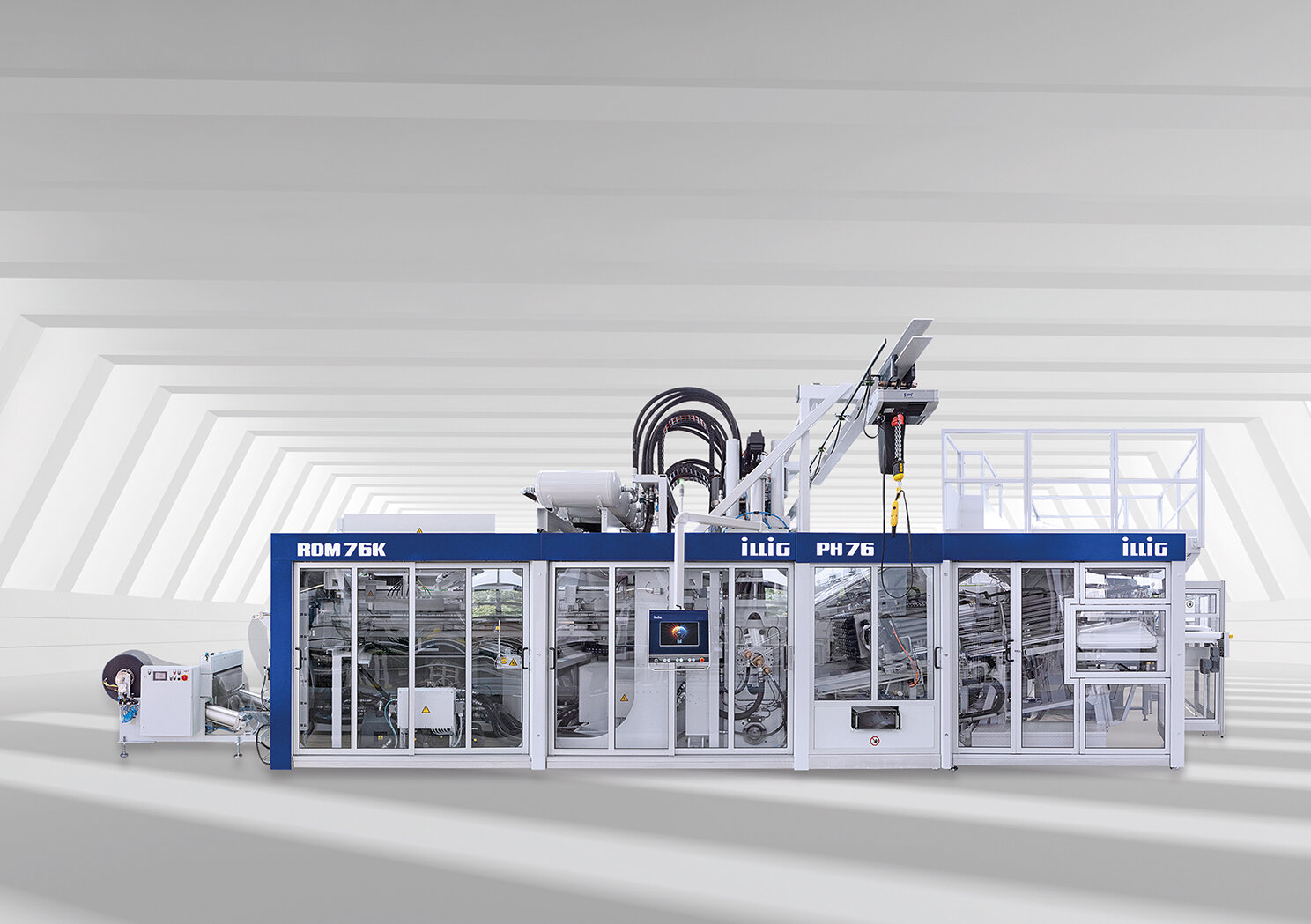

By presenting the 4th Generation RDM 76K automatic roll-fed machine with the newly designed PH 76 and end packaging solution – this is a world premiere at the K 2019 – ILLIG, the global market leader, not only illustrates the next generation in thermoforming, moreover, a further significant stage of development is reached.

The completely re-designed double servo drive of the production system ensures shorter movement times and thus faster cycle times. By using a center support for the lower machine table, ILLIG increased the closing force by 50 percent to 900 kN. As a result, the available cutting length can be increased by up to 50 percent, the service life is extended and productivity is increased. In this 4th Generation system ILLIG also facilitated the material handling. The electronic parallelism setting of upper and lower table reduces secondary times which adds to higher availability. The integrated tool block change system reduces tooling times to less than one hour. In spite of the extended material heating device the total length of the line is reduced compared to the previous series, due to the integration of the newly designed PH 76 product handling device which allows direct interlinkage with different end packaging solutions. At the trade fair the machine produces U-rim drinking cups, 75 mm diameter, 100 mm high, on a 60-up tool of lightweight design, out of 1.3 mm rPET, approved for food contact.

Brilliant lid decoration with IML-T® for the first time

The expansion of the IC-RDK 80 thermoforming system by the new IC-RDKL in-mold labeling unit is a further technological milestone in thermoforming. On this IML-T® production line round labels, 92 mm diameter, are manufactured on a 30-up tool. The lids are brilliantly decorated with paper labels. The labels are made out of 0.35 mm rPET. Manufacturing costs of decorated thermoformed lids are 20 percent lower than costs for injection-molded lids since the weight is substantially lower, the output is higher and machine investment is lower. With IML-T® systems the operator benefits from high flexibility due to fast format and tool changes with low tool costs at the same time. Without use of the IML-T® unit the well-known part range can be manufactured on the IC-RDK 80 thermoforming system. So it is possible to also produce smaller batch sizes of IML-T® lids in an economical way. ILLIG is the world's only one-source supplier of IML-T® thermoforming systems (tool and machine) and responds to the increasing market demand for IML-T® applications by presenting these innovations.

Design4Recycling in the packaging lab

ILLIG is constantly pushing forward with sustainable new developments with aspects of Design4Recycling within the context of Pactivity®, their 360° tailor-made packaging development in thermoforming. In order to make it possible to experience this, ILLIG integrates a packaging lab at the trade fair stand where sustainable solutions will be demonstrated in response to market demand. Among them is the innovative IML-T® Cardboard, a plastic-cardboard combination pack. It consists of a thin plastic inlay and a cardboard that can be decorated on both sides in an attractive way. The application can be manufactured on all ILLIG IML-T® lines and provides new possibilities of decoration technology in thermoforming. A further IML-T® premiere are PET cups decorated with paper labels. After being heated up to 60 degrees Celsius, the labels can be easily separated from the cup. Responsible use of plastics and the pursuit of circular economy are very important considerations for ILLIG; the pioneer in thermoforming. Consequently, ILLIG always regards the development of a thermoformed cup under the aspects of sustainability – from the production stage through to recycling and for material selection the possibilities of optimum package recycling are focal elements. For many years ILLIG has been involved in interdisciplinary packaging development and supports packaging manufacturers in terms of Design4Recycling. Based on the initial product idea ILLIG develops sustainable and economic packaging solutions, designs corresponding tool systems and integrates the tool systems in the optimum „value-adding“ production process with comprehensive service.

ILLIG Toolsys – perfect tool systems

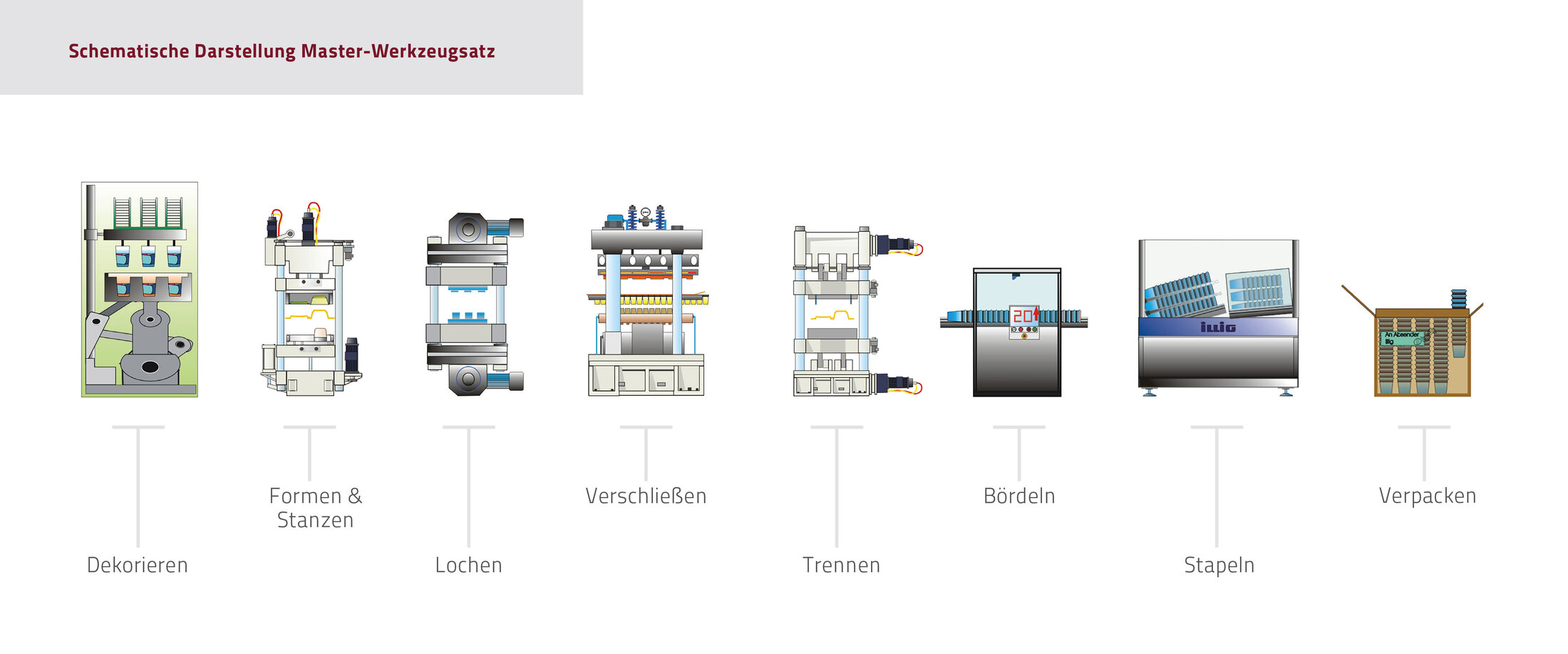

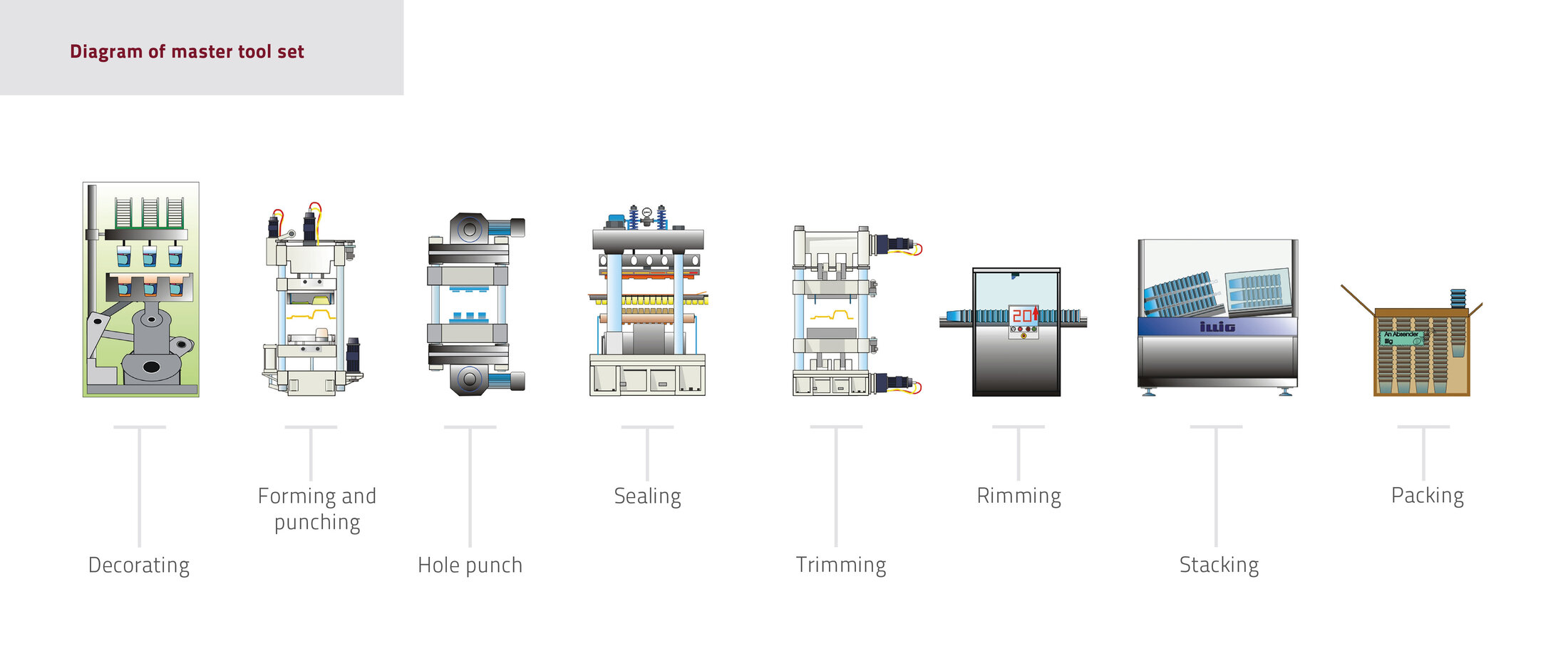

The tool systems which are introduced to the public for the first time under the headword Toolsys at the K 2019, are an increasingly important sector of ILLIG production systems. In the Pactivity process the multitude of tool types required in a production system are perfectly matched. This is an ILLG USP compared to the major competitors in the tool sector. The integrative and coordinated development of tool and thermoforming systems from one source creates synergy effects which finally result in longer service lives of machines and tools. Toolsys offers more productivity, more reliable processes and perfect quality. In the ILLIG tool system all process steps are synchronized. The decisive advantage for customers is the holistic design of the tool system – from cavity, forming tool, label feed (decoration tool), hole punch tool to steel rule and cutting tool. Subject to application and complexity of the process this also includes the sealing tool, stacking tool and part handling system, through to tool change concepts and quick change of forming tools.

Digital transformation in thermoforming

At K 2019 ILLIG will be showcasing developments in digital transformation in thermoforming that aim to significantly increase the overall availability and thus also the productivity of ILLIG systems. ILLIG Connectivity connects the production systems into the customer's networks. Connectivity optimizes order and process control, and facilitates data exchange, data processing, logging and archiving. Derived from the expertise in productivity increase by availability, networking, transparency and use-friendliness, ILLIG transfers the technology of digital transformation in the production process to the thermoforming and packaging systems. The objective is to support and accompany the customers to Industry 4.0.

ILLIG Assist, a support system for operators, is a further step from Connectivity to Industry 4.0. Using this system messages on the machines can be quickly processed and thus an increase in the availability of the thermoforming system can be achieved. Furthermore, a new ILLIG dashboard which combines the production figures of a thermoforming line during operation in a transparent way, displays them for the operator on the screen and allows an optimization of the customer’s production planning. The concept of digital tool administration is also a new feature. A readable RFID tag which is attached to the tool saves the specific data and supports setting of the required tool parameters on the machine for tool changes. Moreover, the digital identification facilitates tool administration. The pioneer in thermoforming will support and accompany you to Industry 4.0.

ILLIG develops demand-oriented solutions and sets the standard for tomorrow’s technology of high-quality and resource-saving thermoforming. Productive, clean, energy-efficient and sustainable

Downloads

About ILLIG

ILLIG is a leading global supplier of thermoforming and packaging systems for the production of sustainable and recyclable plastic and fiber-based packaging. The company's services include the development, design, assembly and commissioning of complex production lines and tools, as well as brand-specific retrofit solutions. Packaging development is at the heart of the business: the company works with customers to develop resource-efficient and sustainable solutions and supports packaging converters in design and production. For more than 75 years, customers have valued the technology company as a reliable and globally active partner. ILLIG stands for innovative technology, top quality and comprehensive global service.

Further information:

Marketing & Communications

Tel.: +49 7131 505-0

E-Mail: media@illig.com

Note: Terms marked with ® are registered and protected trademarks of ILLIG. Pictures: ILLIG