FSL 48 & IML-T®

ILLIG at Anuga FoodTec 2018

Hygienic Packaging of Foods Coupled with Brilliant Decoration

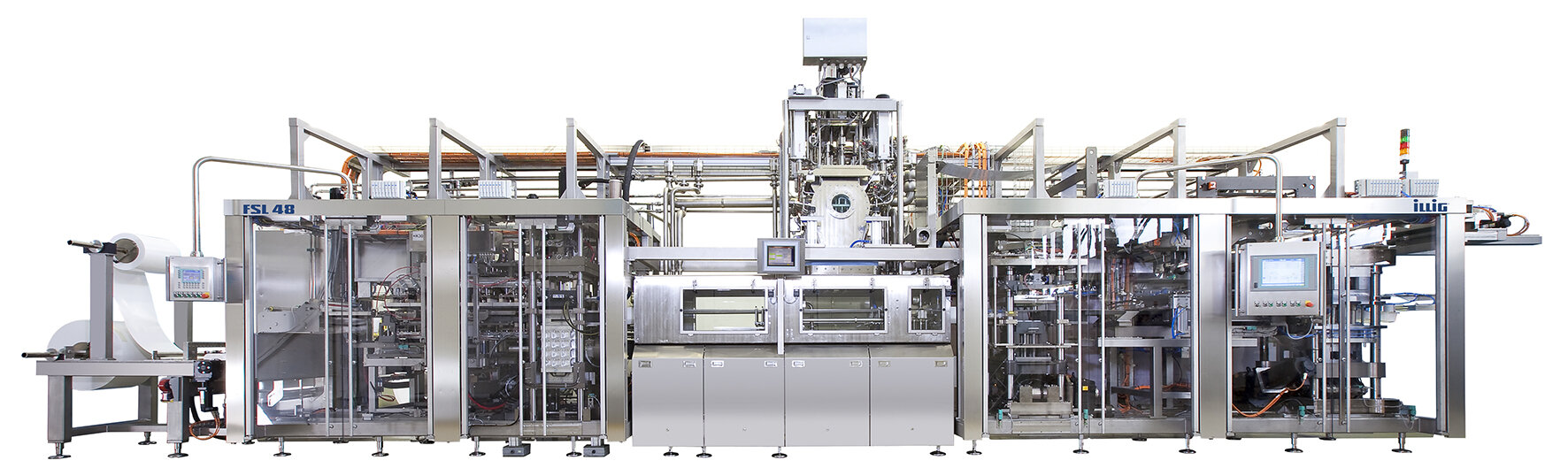

Heilbronn and Cologne, March 2018 – The FSL 48 form, fill and seal line will take center stage at the ILLIG stand at this year's Anuga FoodTec exhibition in Cologne from March 20 to 23, 2018. The FFS line was designed for the food industry, and in particular for the dairy industry. All in one step, the production system decorates the packaging in brilliant picture quality during the thermoforming process with in-mold-labeling (IML-T®), hygienically fills the food in the packaging and seals it – ready for the shelf at the point of sale (PoS).

The levels of hygiene of the FSL 48 range from forming the IML-T®-decorated cups with sterilized air, to the complete enclosure of the filling area, to the sterilization of the lid material with ultraviolet germicidal irradiation. The multi-lane filler is designed for CIP (clean-in-place) and SIP (sterilization-in-place), and thus ideal as an aseptic filling line. This ensures compliance with standards up to hygiene class V according to VDMA (Mechanical Engineering Industry Association – hygienic filling machines) when filling and packaging with the FSL 48. The multi-lane filler can fill up to eight different product types simultaneously.

The FSL 48 can process all standard material films suitable for FFS lines, such as PS, PP, multilayer material (e.g. PS / EVOH / PE), APET and films made of the biopolymer PLA (polylactic acid). This also applies to heat sealable lid material films.

The format area of 480 mm x 320 mm (up to 350 mm for undecorated packaging) is designed so that after the process of sealing and trimming the packaging tape, the filled and sealed cups of a complete machine cycle – for example, twelve standard containers of quark – can be put into a box the size of a EUR-pallet. The format area can accommodate single or double cups, or four- or six-pack trays. The controlled motion sequences of the fully servo-driven machine line enables very smooth operation, so that even liquid products with a very low viscosity can be filled at speeds of over 30 cycles per minute without spilling and contaminating the sealing edges. Molds with up to 24 cavities are already being used by customers on the FSL 48.

IML-T®: Individual and Brilliant Decorating of a Wide Variety of Molded Part Geometries

Designed for the FSL 48, the IML-T® unit works with pre-printed and pre-cut labels that are taken from a magazine and inserted into the mold cavities. During the subsequent forming of the cups, the labels are permanently joined together with the cup wall. As the IML-T® decoration does not require any vertical walls, this decorative technique also gives you the advantage of being able to individualize your product's visual appearance so that it stands out from all the others on the grocery store shelf at the PoS. The IML-T® technology gives you all kinds of new possibilities to decorate your cups: one-sided, two-sided, three-sided (e.g. U-shape), four- or even five-sided (including the bottom, for example, with an integrated barcode), combining high-quality visual art with functionality. PP, PS as well as PET or paper labels can be processed to match the cup material. Since the IML-T® unit is integrated into the forming station, it requires no more floor space than a conventional banding unit.

Another advantage of the IML-T® technology is that it lets you use a different pre-printed label for each mold cavity. This versatility is ideal for filling and packaging entire product families, which is made possible by the line's multi-lane filler. Changing products can be done quickly and easily.

About ILLIG

ILLIG is a leading global supplier of thermoforming and packaging systems for the production of sustainable and recyclable plastic and fiber-based packaging. The company's services include the development, design, assembly and commissioning of complex production lines and tools, as well as brand-specific retrofit solutions. Packaging development is at the heart of the business: the company works with customers to develop resource-efficient and sustainable solutions and supports packaging converters in design and production. For more than 75 years, customers have valued the technology company as a reliable and globally active partner. ILLIG stands for innovative technology, top quality and comprehensive global service.

Further information:

Marketing & Communications

Tel.: +49 7131 505-0

E-Mail: media@illig.com

Note: Terms marked with ® are registered and protected trademarks of ILLIG. Pictures: ILLIG