17th Open House

17th ILLIG Open House 2018

Therformance – Performance in Thermoforming:

ILLIG presents several world premieres

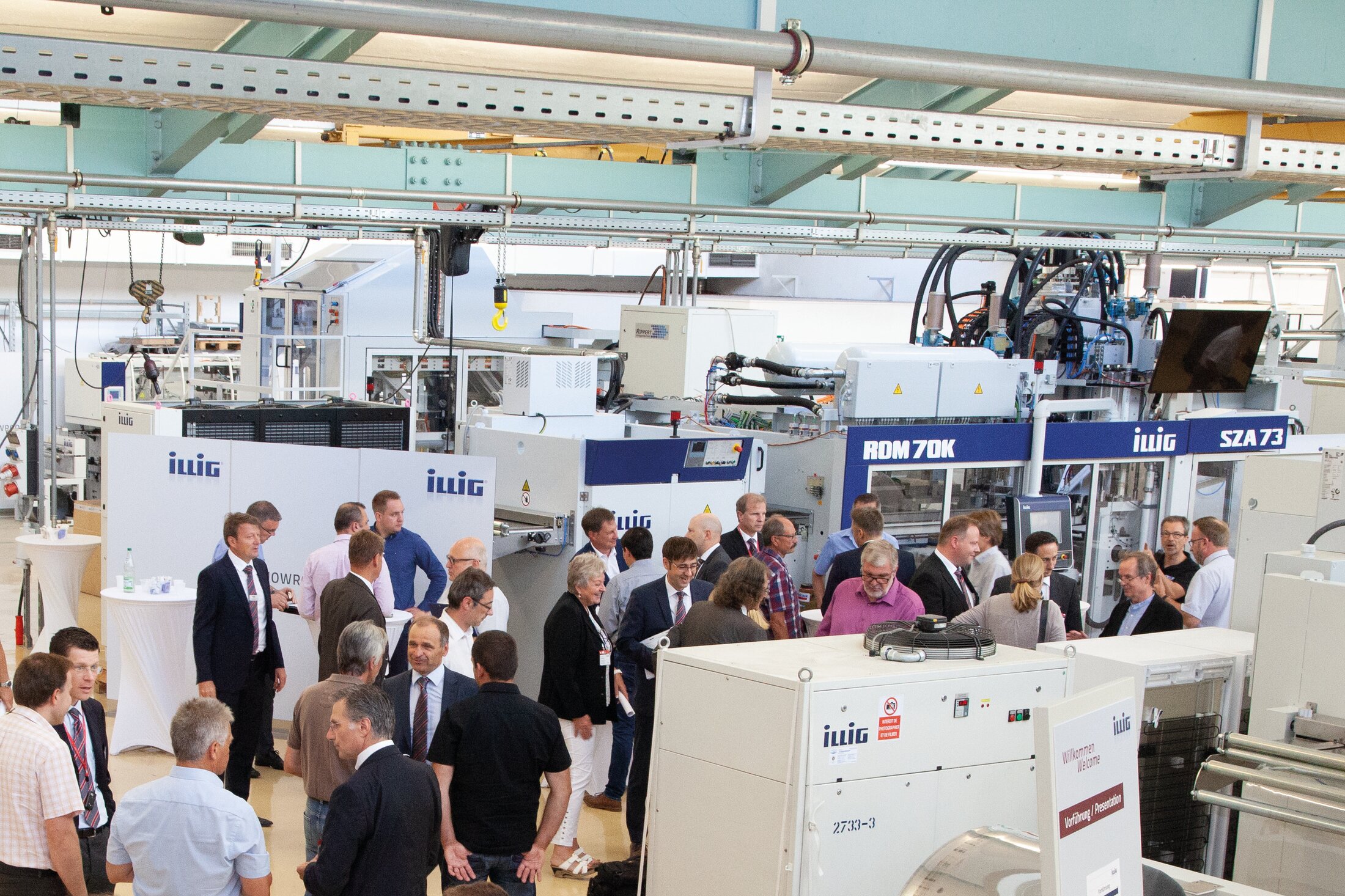

Heilbronn, June 20, 2018 – ILLIG Maschinenbau, the thermoforming systems supplier will be showcasing several world premieres on occasion of their 17th Open House, Heilbronn, June 20 and 21, 2018. The company will give the customers insight into innovative high-performance thermoforming lines and intelligent solutions at a total of 12 stations in the following sectors: Engineering, packaging technology, packaging development, mold making and service. This is an exhibition at the highest level with machine demonstrations under production conditions. And ILLIG consistently proceed with the application of the Cleantivity® concept (cleanliness and productivity) as well as the Pactivity® packaging development (360° custom-made packaging development in thermoforming). Technological highlights include the new IC-RDM 73K thermoformer with increased output and reduced tool change time and the new IC-RD 74 automatic pressure forming machine with controllable compressed air support up to 3 bar. Again, the machine manufacturer expects to welcome more than 200 invited visitors from all over the world to this two-day event.

World premiere no. 1: IC-RDM 73K

At the Open House ILLIG will be showcasing the new IC-RDM 73K automatic roll-fed machine with high output and a quick-change system for molds. Compared to the IC-RDM 70K machine, the forming area of the new machine was enlarged by 23 percent. Further technical innovations are shorter movement times of the forming device, extended material heating tunnel, optimized forming air technology and mold cooling as well as the use of a lightweight mold. All of these improvements together contribute to a up to 25 percent increased production performance, subject to application. A new, easy to use system for block change of molds reduces tool installation and removal times by more than 50 percent, i.e. the change can be performed in less than 60 minutes. The fast and easy mold change is supported by a tool change axis, an optimized adjustment of the upper table as well as a lower table which is equipped with support air elements. Moreover, ILLIG consistently implemented the Cleantivity® concept in the

IC-RDM 73K, with features such as optimized material piercing, machine temperature control and condensation protection. At the Open House 1.020 PP yogurt cups (1.35 mm) will be produced on the line using a 30-up mold, at a speed of 34 cycles per minute.

World premiere no. 2: IC-RD 74

The IC-RD 74 pressure forming machine is a further innovation. This machine was developed based on ILLIG Cleantivity® criteria and is equipped with the ILLIG Intelligent Control Concept® (ILLIG IC-Concept®). The machine produces high-quality parts at a speed of up to 35 cycles/min supported by controllable 3 bar compressed air support. The mold can be changed fast and easily and thus stand-still times are minimized. The use of simple and cost-effective molds for smaller and medium batch sizes is a further benefit. At the Open House the machine will be operated at a speed of 30 cycles and 240 lunch boxes (hinged packs) of superior quality will be produced per minute out of APET (0.35 mm), using an 8-up mold.

World premiere no. 3: New packaging lab provides focus for Pactivity® activities

On occasion of the Open House ILLIG launches the new, state-of-the-art packaging lab, located close to the expanded customer center. This allows a concentration of ILLIG’s Pactivity® activities around the packaging development sector and thus even more options are provided for product development together with customers. A 3D printer makes initial and fast realization of product ideas possible. Moreover, material properties of thermoformed plastics can be analyzed in the lab by means of optical scanner, microscope, polariscope and microtome, as well as a tensile testing machine. The equipment further includes a heating cabinet for determination of shrinkage as well as devices to check tightness and top-load of formed parts. ILLIG experts with their long-term experience and technical know-how can thus provide custom-made 360° advisory service and support to customers for high-quality and marketable packaging solutions through to realization of solutions by means of corresponding production systems and molds.

ILLIG Service

ILLIG provide innovative impetus to customers for a profitable future and they also offer technology and service from one source for thermoforming of plastic materials. Besides specialists stationed all over the world and a global spare parts supply, the comprehensive service portfolio also includes technical training, process consulting and service offers through to support during ongoing production by remote diagnosis. ILLIG service and machine upgrades ensure high availability and productivity of the lines for many years.

Who´s who in the industry

The annual ILLIG Open House developed into the who´s who in the thermoforming sector. The in-house event provides the unique opportunity to experience most of the state-of-the-at high-performance thermoforming systems under production conditions. The Heilbronn company, leader in thermoforming, sets the standard in machine and mold manufacturing. This is revealed by the response at the leading trade fairs K, Interpack, NPE and Chinaplas. „We export more than 60 percent of our thermoforming systems to non-European countries. There is a considerable interest in our reliable ILLIG technology and our brands at the international plastic and packaging fairs“, says managing director Karl Schäuble. During the 70 years since its foundation ILLIG has developed into the innovation leader of the thermoforming sector. With pioneering spirit, innovative ideas and reliable technical quality, ILLIG sets the standard in the sector. This also becomes evident in terms of economic development: „In 2016 and 2017, ILLIG could increase sales by more than 10% each which is clearly above the industry average.“ According to the current state, there will be a further record year after that of 2017. „Our order books are really filled, our technology is in demand worldwide“, Schäuble explains.

The technical development during the last years, the increased demand for thermoforming systems on the part of all product sectors and, above all, the good economic development of non-European markets contributed to this. Karl Schäuble: „We expect that the thermoforming technology, especially in the packaging sector, will be gaining more and more importance since it is possible to reduce material consumption in this way and there are new solutions with regard to part design and decoration technology. We continue to expect that for most of our customers an increase in productivity is very important. To achieve this, we will further increase speeds in thermoforming and punching processes, since this is how quality and reproducibility of formed parts can be improved. Existing and currently developed quick change technologies for molds meet market trends for decreasing batch sizes“.

ILLIG sets the standard for tomorrow’s technology of high-quality and resource-saving thermoforming. Productive, clean, energy-efficient and sustainable.

About ILLIG

ILLIG is a leading global supplier of thermoforming and packaging systems for the production of sustainable and recyclable plastic and fiber-based packaging. The company's services include the development, design, assembly and commissioning of complex production lines and tools, as well as brand-specific retrofit solutions. Packaging development is at the heart of the business: the company works with customers to develop resource-efficient and sustainable solutions and supports packaging converters in design and production. For more than 75 years, customers have valued the technology company as a reliable and globally active partner. ILLIG stands for innovative technology, top quality and comprehensive global service.

Further information:

Marketing & Communications

Tel.: +49 7131 505-0

E-Mail: media@illig.com

Note: Terms marked with ® are registered and protected trademarks of ILLIG. Pictures: ILLIG