NEXT 75 | ILLIG Sustainably Shapes the Future

75 Years ILLIG Maschinenbau

This year, the Heilbronn-based mechanical engineering company ILLIG celebrates 75 years of successful operations around the globe. With the anniversary motto "Next 75", the company is consciously looking ahead to extend its market leadership in the decades to come. In this anniversary year, customers, partners and employees are looking forward to more success.

75 years ago, on May 27, 1946, Adolf Illig founded a mechanical repair shop, thus creating the basis for the company that would become a world leader. The founding father recognized the needs of his customers, constantly realigned his services to these needs, and expanded the technical expertise of his company. The workshop grew into a prosperous mechanical engineering company and quickly established itself as a market leader in thermoforming technology while creating a recognized brand. ILLIG is regarded as the inventor of industrial thermoforming, a name that still stands for safe and secure, high-quality thermoforming and tooling systems as well as innovative, sustainable, and reliable packaging solutions. With its continued investments in new technologies, innovative solutions, and numerous patents, the Heilbronn-based company holds the top position in the industry and, according to a recent survey by the F.A.Z. Institute, is once again recognized as being one of the most innovative companies in Germany. In this anniversary year and beyond, new developments are expected to set milestones in the thermoforming industry.

Setting the pace in thermoforming technology

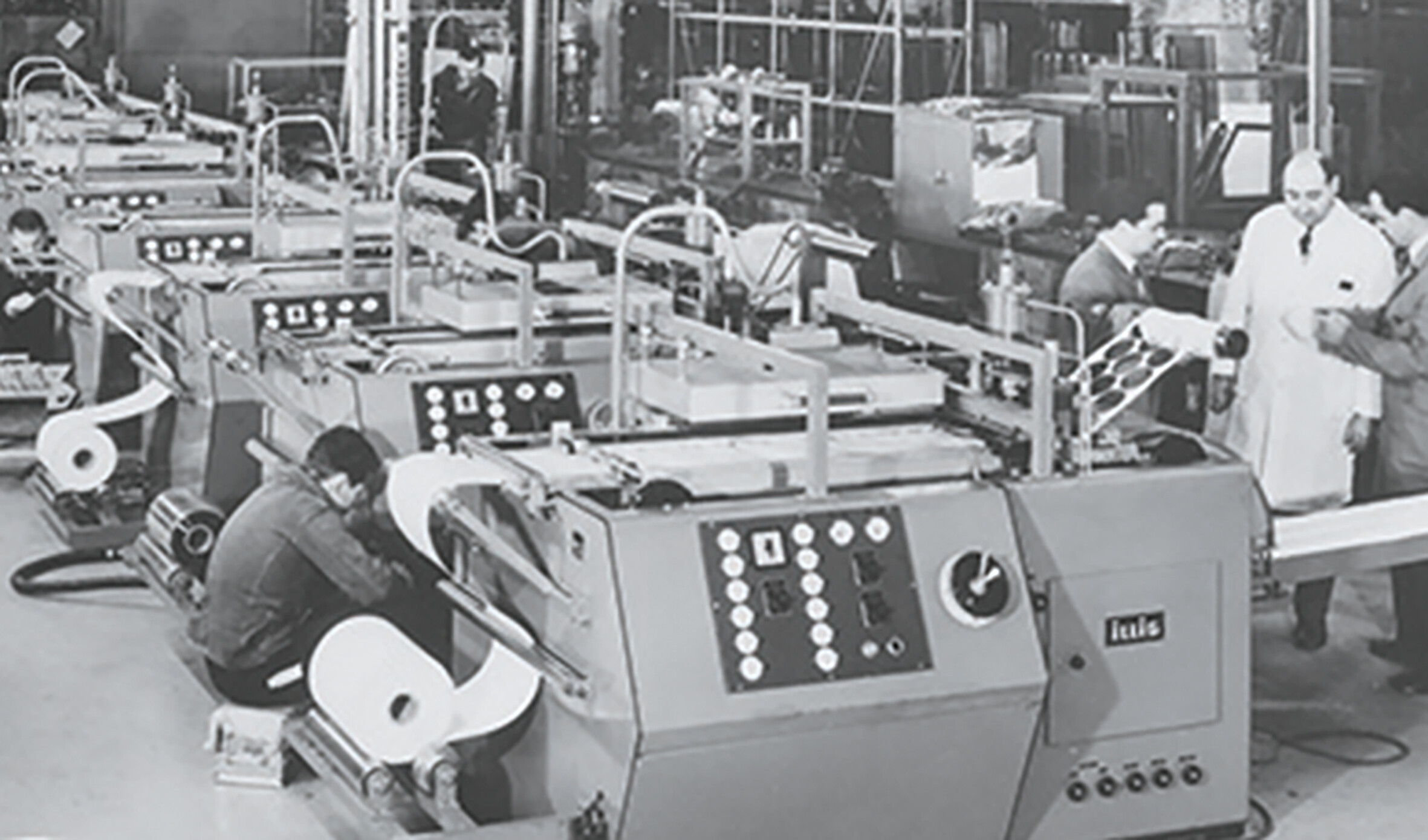

ILLIG took off in 1956 with the construction of the first ILLIG UA 100 vacuum forming machine. In the following years, the company developed further trend-setting thermoforming machines. As early as 1960, the world's first roll-fed automatic vacuum forming machine, designed for the series production of lids from pre-printed film, was developed in the form of the R 650 machine series. This was followed just three years later by the first automatic pneumatic quick-forming machine for combined forming and die-cutting operations. This marked the birth of the successful RDM series, which is still regarded as the benchmark for cost-effective, large-scale production.

At the end of the 1970s, the machine program was expanded with the first packaging line that integrated the forming of basic packages with subsequent filling and sealing to produce finished consumer packaged goods.

In 1984, ILLIG created a new standard for hygiene in packaging with the invention of mold tilting technology in thermoforming machines. The first machine of this type, the RDM 50K, was a milestone and unique in the industry. In 1989 ILLIG developed programs for the automatic calculation of basic settings to enable the simplest operation of vacuum thermoforming machines which have been the standard in modern plants ever since.

New millennium with ILLIG milestones

At the beginning of the nineties, decoration technology in the form of In-Mold Labeling arrived. IML-T® is now established as a unique packaging advantage for point of sale items, especially for dairy products. Soon after this pioneering achievement, ILLIG built the first fully aseptic form, fill and seal (FFS) machine with a daily capacity of 700,000 yogurt pots – a world record at the time.

In the first years of the new millennium, the company set new standards with its 3rd generation thermoformers, with significantly increased productivity and quality of formed parts due to the consistency and reproducibility of machine settings. This was achieved through advanced servo-motor drives and motion control techniques, which also improved energy efficiency.

A particularly dynamic area driving innovation is the packaging sector. Developments such as the ILLIG Bottle Former BF 70 or the integration of IML-T® decoration technology into FFS lines are representative of advanced packaging technology at ILLIG.

A technological quantum leap was achieved in 2013 with the introduction of “Intelligent Control” (ILLIG IC) which offers the highest operating performance at the push of a button. In 2017, ILLIG bundled its customized packaging development activities with “Pactivity® 360”, supporting customers from initial concept to final production. In 2018, a new flexible packaging system was introduced, enabling the production of combination packs such as plastic/cardboard blisters and all paper blisters. In 2019, the first 4th generation thermoformer with higher die punching force and performance was launched at the K trade fair in Dusseldorf.

Next 75 – even closer to the customer with innovative developments

ILLIG is a family-owned firm now in the third generation. Since 2020, managing directors Carsten Strenger (CEO) and Jürgen Lochner (CSO/CTO), appointed by the Illig and Schäuble families, have been leading the company into the future. Both leaders are placing even more emphasis on customer engagement and market-oriented products at ILLIG. "We are consistently pursuing the path of efficient operational process design in order to be even closer to the customer," explains Jürgen Lochner. Structurally, the two managing directors continue to align the family-owned company with sustainable solutions, aligned with Circular Economy principles, which perfectly serve the needs of global markets. "Challenges stemming from worldwide uncertainty in the markets due to the ongoing plastics discussion and the economic impact of the Corona pandemic are well-known," adds Carsten Strenger. "It's a matter of being highly flexible and strategically focused in responding to customer requirements derived from these global market realities," he says.

Next 75 – Circular Thinking with ILLIG

Customized packaging development (“Pactivity® 360”) and tool development programs (Toolsys®) make a significant contribution to ILLIG’s holistic approach to packaging. With Circular Thinking, ILLIG supports sustainability goals:

Reduce - Reuse - Separate - Recycle and Renew.

"ILLIG mold, machine, and packaging systems are flexible in terms of materials. They process biodegradable plastics, recycled goods, plastic-cardboard combinations or post-consumer films in a process-safe manner, including pure cardboard applications," explains Jürgen Lochner. The latest application developments with plastic-cardboard combinations of the I-PACK® brand (ILLIG intelligent packaging) underline this development. These new packaging systems support the sustainability strategies of ILLIG customers worldwide with the possibilities to produce full carton blisters or plastic-cardboard blister combinations.

"Today, ILLIG offers a comprehensive, mature, and modular machine program to produce almost all sustainable packaging required today. With our know-how, which has grown over 75 years of company history, we will continue to be committed to the evolution of this versatile technology," says Carsten Strenger, looking to the “Next 75” with confidence.

The latest innovation from our company is the production of packaging from thermoformable paper on existing production equipment, a development that dovetails with the current sustainability strategies of global companies operating in diverse markets around the world.